How to Use Vibrated Concrete for Durable Construction Projects

In the realm of construction, achieving durability and strength is paramount for any project, and one innovative solution that has gained prominence is the use of Vibrated Concrete. This technique involves the application of vibration during the concrete pouring and setting process, significantly enhancing the material's density and structural integrity. By optimizing the distribution of aggregates and minimizing air pockets, Vibrated Concrete offers a robust alternative to traditional methods, making it particularly suitable for demanding environments and heavy-load applications.

The advantages of Vibrated Concrete extend beyond mere strength; this method also allows for greater versatility in design and formwork. As it flows easily into molds and corners, it enables the creation of intricate structures that meet a variety of architectural demands. Additionally, the improved compaction results in a lower permeability, which is crucial for combating environmental challenges such as moisture intrusion and freeze-thaw cycles. As we delve deeper into the utilization of Vibrated Concrete, we will explore its benefits, applications, and best practices that ensure long-lasting construction outcomes.

Understanding Vibrated Concrete and Its Benefits for Construction

Vibrated concrete is becoming increasingly popular in construction due to its unique properties that enhance durability and longevity. The process involves using mechanical vibration to consolidate concrete, allowing air bubbles to escape and ensuring a denser final product. According to a report by the American Concrete Institute, vibrated concrete exhibits a compressive strength that can be up to 30% higher than conventional methods. This increased strength translates to improved performance in structures subjected to stress, including high-rise buildings and bridges.

Additionally, vibrated concrete enhances the overall durability of construction projects by minimizing the occurrence of voids and improving overall density. The International Journal of Concrete Structures and Materials highlights that structures built with vibrated concrete often show a 20-50% increase in resistance to water penetration. This makes it an ideal choice for projects in regions prone to heavy rain or flooding, as it helps prevent moisture-related damage. By using vibrated concrete, contractors can ensure that their projects not only adhere to higher standards of safety but also promote sustainability through materials that last longer and require less maintenance over time.

Durability of Concrete Types in Construction

This chart illustrates the durability of various types of concrete used in construction projects. Vibrated concrete shows a remarkable lifespan of up to 50 years, significantly surpassing the traditional standard concrete's durability of 20 years.

Essential Tools and Equipment for Vibrating Concrete Effectively

When working with vibrated concrete, having the right tools and equipment is crucial for achieving optimal results in construction projects. At the core of these tools are vibrators, which come in various forms including internal, external, and surface vibrators. Internal vibrators are typically used for pouring concrete in thicker slabs, while external vibrators are ideal for precast applications. Surface vibrators, on the other hand, are commonly used for finishing concrete surfaces, ensuring a smooth and even application of vibrated concrete.

In addition to vibrators, other essential equipment includes concrete mixers, which are vital for achieving a homogenous concrete mix prior to vibration. Using the correct type of mixer ensures that the mixture maintains a consistent density, allowing for effective vibration. Furthermore, having access to a reliable level and measuring tools is crucial for ensuring the accurate placement and alignment of concrete when using vibrated methods. Together, these tools and equipment facilitate the creation of durable concrete structures that can withstand the test of time, improving both the efficiency and quality of construction projects.

How to Use Vibrated Concrete for Durable Construction Projects - Essential Tools and Equipment for Vibrating Concrete Effectively

| Tool/Equipment |

Description |

Purpose |

Common Use Cases |

| Concrete Vibrator |

Electrical or gasoline-powered tool used to create vibrations in fresh concrete. |

To increase the density and reduce air pockets in the concrete mix. |

Slabs, walls, and large structural elements. |

| Needle Vibrator |

A smaller, handheld vibrator ideal for tight spaces and vertical elements. |

To ensure proper compaction in hard-to-reach areas. |

Column and thin wall construction. |

| Plate Vibrator |

Vibrator with a flat base, typically used for larger surfaces. |

To compact layers of concrete and soil. |

Pavements and parking lots. |

| Form Work |

Temporary or permanent mold into which concrete is poured. |

To hold the concrete in place until it sets. |

All types of concrete structures. |

| Concrete Mix Design |

Proportions of materials in the concrete mix. |

To achieve desired strength, workability, and durability. |

Varies based on project specifications. |

Step-by-Step Guide to Mixing and Pouring Vibrated Concrete

Vibrated concrete is an essential material for achieving durability in construction projects, particularly in environments that demand resilience against various stresses. The mixing and pouring process of vibrated concrete plays a critical role in ensuring optimal consolidation and strength. To begin, it is vital to select the right components—Portland cement, aggregates, and water—while adhering to a mix design that typically follows the guidelines of standards such as ASTM C941. According to industry reports, using a water-cement ratio of 0.4 to 0.5 can significantly enhance the durability and compressive strength of the concrete, providing it with long-lasting endurance.

Once the mixing is complete, pouring the concrete requires attention to detail. It is recommended to transport the concrete to the pouring area quickly to prevent initial setting. Utilizing vibration during this phase is crucial, as it helps eliminate air pockets and ensures a uniform distribution of aggregates, further enhancing the mixture’s overall performance. Industry studies suggest that well-vibrated concrete can lead to up to a 30% increase in compressive strength compared to poorly compacted mixes. To effectively use this technique, it's advisable to carefully monitor the vibration process, maintaining an optimal frequency and amplitude to avoid segregation while facilitating adequate compaction. Such precision in mixing and pouring is key to achieving durable construction outcomes that can stand the test of time.

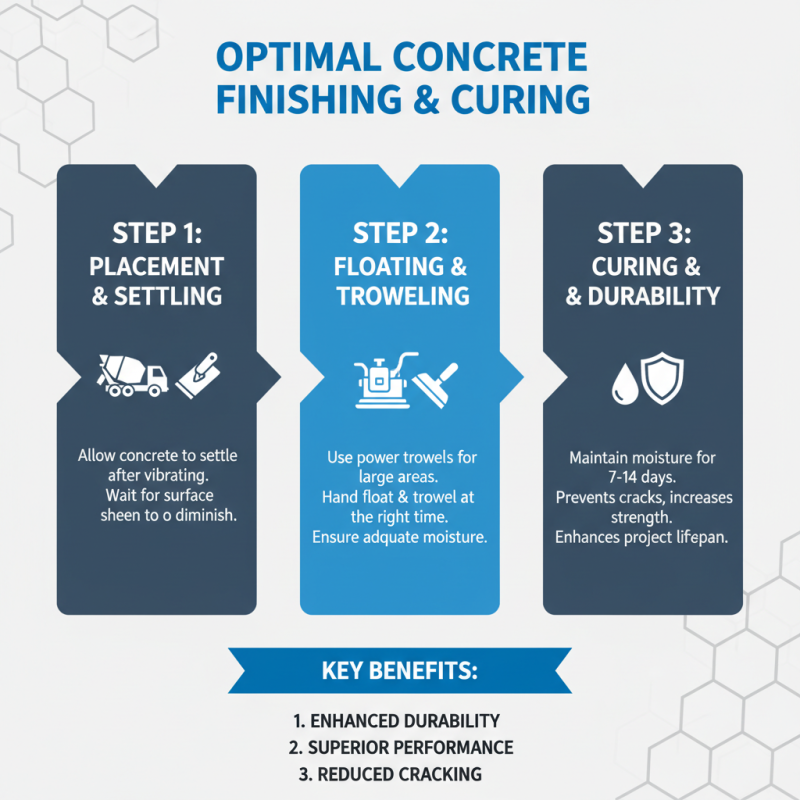

Best Practices for Finishing and Curing Vibrated Concrete

Finishing and curing vibrated concrete are crucial steps that significantly enhance the durability and performance of construction projects. To ensure an optimal finish, the concrete should be allowed to settle after initial placement. The use of power trowels can help achieve a smooth surface, especially for large areas. It is essential to employ techniques such as floating and troweling during the appropriate curing periods to avoid damage to the concrete. Timing is vital; finishing work should be done when the surface sheen begins to diminish, ensuring that the concrete retains adequate moisture while allowing for proper leveling.

Curing vibrated concrete effectively involves maintaining the right moisture levels to prevent cracks and surface defects. Common curing methods include applying curing compounds, wet burlap, or water-soaked mats to keep the surface damp. The duration of the curing process significantly influences the concrete's strength; typically, curing should last for at least seven days. Moreover, it's important to avoid rapid temperature changes during this period. Monitoring environmental conditions and shielding the concrete from direct sunlight can further aid in achieving a strong, durable finish, minimizing the risk of shrinkage and promoting better overall performance of the structure.

Common Challenges in Vibrated Concrete Application and Solutions

Vibrated concrete is widely recognized for its durability and strength in construction, but its application does come with a range of challenges. One of the most common issues faced during the use of vibrated concrete is achieving consistent compaction, particularly in intricate forms or when using complex reinforcing systems. According to the American Concrete Institute, improper vibration can lead to inadequate consolidation, resulting in voids and weak points within the concrete matrix. This risk emphasizes the need for careful monitoring and application of vibration techniques to ensure even distribution of the mix.

Another significant challenge lies in the proper selection and mixing of materials. The performance of vibrated concrete can be adversely affected by the quality and compatibility of aggregates and admixtures used in the mix. As highlighted in the "Concrete Technology and Construction Report," nearly 30% of construction projects faced delays due to issues arising from poor material quality and inadequate mix design, leading to compromised structural integrity. To mitigate this problem, employing rigorous testing methods before the mixing process can identify material deficiencies, thus ensuring the resulting concrete meets the desired standards for performance and longevity.

Addressing these challenges requires a proactive approach, including training for construction teams on the nuances of vibrated concrete, regular inspection of both the mixing process and end product, and incorporating advanced technologies like digital monitoring systems. These measures not only enhance the quality of the output but also contribute to the overall efficiency and success of construction projects, ultimately leading to safer and more durable infrastructures.

Home

About Us

products

Resource

Blog

Contact Us

Internal Vibrator

Internal Vibrator

External Vibrator

External Vibrator

Submersible Pump

Submersible Pump

Eccentric shaft

Eccentric shaft

Pendulum shaft

Pendulum shaft

Portable vbrator shaft

Portable vbrator shaft

Portable concrete mixer

Portable concrete mixer

Vertical concrete mixer

Vertical concrete mixer

Hydraulic concrete mixer

Hydraulic concrete mixer

Walk behind power trowel

Walk behind power trowel

Ride on power trowel

Ride on power trowel

Concrete screed

Concrete screed

Tamping rammer

Tamping rammer

Plate compactor

Plate compactor

Vibratory roller

Vibratory roller