Top Diesel Concrete Vibrators for 2025 Which One is Right for You

In the construction industry, the integration of advanced machinery has revolutionized traditional methods, particularly in concrete compaction. Among these innovations, the Diesel Concrete Vibrator stands out for its efficiency and effectiveness. According to a recent report by the Construction Equipment Industry Association, the demand for concrete vibrators has surged by over 25% in the past three years, signaling a significant shift towards more robust and durable construction practices. As industry experts predict, 2025 will see further advancements in this technology, driving more contractors to consider which Diesel Concrete Vibrator is best suited for their specific needs.

Renowned industry expert Dr. Emily Zhao emphasizes the importance of selecting the right Diesel Concrete Vibrator for optimal results: "The effectiveness of concrete compaction not only depends on the machine but also on understanding the environment and conditions of the job site." This insight highlights the necessity for contractors to analyze their project's requirements carefully. With various models and specifications hitting the market, understanding the features and benefits of each option will be crucial for making informed decisions. As we approach 2025, navigating this evolving landscape will be vital for achieving high-quality and durable concrete structures.

Overview of Diesel Concrete Vibrators and Their Importance

Diesel concrete vibrators play a crucial role in the construction industry by ensuring optimal compaction of concrete. The process of vibrating concrete assists in eliminating air bubbles and voids, leading to a denser, stronger final product. According to industry reports, improper compaction can reduce the concrete's compressive strength by up to 50%, significantly impacting structural integrity. The versatility of diesel-powered models enables them to be used in various applications, from small projects to large-scale infrastructure developments, making them an essential tool for contractors and builders.

When selecting a diesel concrete vibrator, consider the specific requirements of your project. Look for models that offer adjustable frequency and amplitude rates, as this allows for customized vibration effects suited to different concrete mixtures and depths. Furthermore, ease of maintenance should be a priority; reliable performance and longevity are crucial in minimizing downtime during critical phases of construction.

Tips: Ensure you conduct proper training for operators to maximize the effectiveness of diesel concrete vibrators. Proper technique reduces the risk of over-vibration, which can harm the concrete structure. Additionally, regular maintenance checks should be scheduled to ensure your equipment is in optimal working condition, thus preventing unexpected failures on-site.

Key Features to Consider When Choosing a Diesel Concrete Vibrator

When selecting a diesel concrete vibrator, there are several key features to consider to ensure optimal performance and efficiency. First and foremost, the engine power is a critical factor, as it directly affects the vibrator’s ability to forge concrete into a dense and durable structure. A higher horsepower engine may provide greater vibration amplitude, making it more effective for larger projects or challenging mix designs. Therefore, balancing engine power with the nature of your specific workload is essential in your selection process.

Another important aspect is the type of vibrator head. Options typically range from internal to external vibrators, each serving different applications. Internal vibrators are ideal for consolidating concrete within a mold, while external vibrators may be more suited for particularly large or complex structures. Additionally, considering the vibration frequency is essential; a higher frequency can lead to better consolidation without risking segregation of the concrete mixture. Ease of use and maintenance should also not be overlooked – robust construction for durability and user-friendly design can greatly enhance productivity on the job site.

Top Diesel Concrete Vibrators for 2025

Top Brands for Diesel Concrete Vibrators in 2025

In 2025, the market for diesel concrete vibrators continues to grow, driven by increased construction activities around the globe. According to recent industry reports, the demand for durable and efficient equipment like diesel concrete vibrators is anticipated to rise by approximately 8% annually. This surge is attributed to their effectiveness in eliminating air bubbles and ensuring a denser concrete mix, which is essential for structural integrity and long-term durability.

When selecting the right diesel concrete vibrator, it's crucial to consider the brand's reputation for quality and reliability. Some of the top manufacturers have consistently received high marks for performance and customer satisfaction, often noted in dealer surveys. These brands prioritize advanced engineering and customer feedback, leading to innovations in vibration technology that result in better compaction and improved operator comfort.

Tips: Always evaluate the specifications of the vibrator, including its engine power, a frequency of vibration, and weight, to match the demands of your concrete project. Furthermore, pay attention to after-sales support and availability of spare parts, as these factors significantly influence operational efficiency. Regular maintenance is also key—establish a routine check-up to ensure optimal performance and longevity of the equipment.

Comparative Analysis of the Leading Models Available

When it comes to selecting the right diesel concrete vibrator for your projects in 2025, a comparative analysis of the leading models can provide valuable insights. Diesel concrete vibrators are predominantly utilized for their efficiency in consolidating concrete, ensuring optimal strength and durability. Factors such as engine power, vibration frequency, and fuel efficiency play crucial roles in determining the ideal model for different application needs. Models vary in design, including options with higher portability for smaller job sites or robust units intended for larger scale operations.

Performance reliability is another essential aspect to consider, as it directly impacts productivity and project timelines. A thorough evaluation of user feedback often reveals how well a model stands up to heavy-duty use, as well as its maintenance requirements over time. Additionally, considering features such as ease of starting, noise levels, and user ergonomics can help in making an informed choice. By analyzing these aspects, you can identify which diesel concrete vibrator aligns best with your operational objectives and work environment, ensuring a successful concrete pouring and finishing process.

User Experiences and Expert Reviews on Diesel Concrete Vibrators

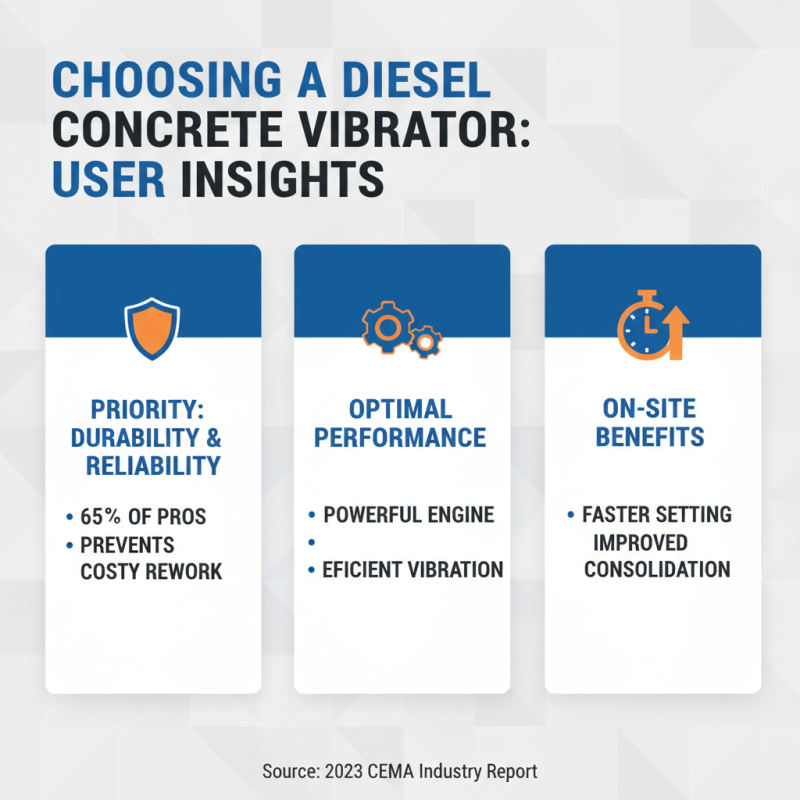

When choosing a diesel concrete vibrator, user experiences play a critical role in decision-making. According to a 2023 industry report from the Concrete Equipment Manufacturers Association, more than 65% of professionals in construction prioritize the durability and reliability of a vibrator, citing incidents where subpar models led to uneven concrete finishes and costly rework. Many users have shared that a powerful engine paired with an efficient vibration mechanism significantly enhances their productivity on-site, allowing for faster setting times and improved concrete consolidation.

Furthermore, expert reviews highlight key features that resonate with both seasoned contractors and newcomers alike. A recent study indicated that vibrators with a weight range of 70 to 90 pounds are optimal for achieving satisfactory performance without sacrificing mobility. Users frequently commend designs with anti-vibration technology that improves operator comfort during extended use. This focus on ergonomics is particularly crucial, as research shows that prolonged use of heavy machinery can lead to musculoskeletal injuries, leading many to favor models that promote safer handling without compromising on power.

In conclusion, when selecting the right diesel concrete vibrator for 2025, considering user experiences and expert insights significantly aids in making an informed choice that balances performance, ergonomics, and overall efficiency on the job site.

Home

About Us

products

Resource

Blog

Contact Us

Internal Vibrator

Internal Vibrator

External Vibrator

External Vibrator

Submersible Pump

Submersible Pump

Eccentric shaft

Eccentric shaft

Pendulum shaft

Pendulum shaft

Portable vbrator shaft

Portable vbrator shaft

Portable concrete mixer

Portable concrete mixer

Vertical concrete mixer

Vertical concrete mixer

Hydraulic concrete mixer

Hydraulic concrete mixer

Walk behind power trowel

Walk behind power trowel

Ride on power trowel

Ride on power trowel

Concrete screed

Concrete screed

Tamping rammer

Tamping rammer

Plate compactor

Plate compactor

Vibratory roller

Vibratory roller