Top 10 Compactor Machines: Importance, Types, and Buying Guide

In the construction and waste management industries, a Compactor Machine plays a crucial role. These machines compress materials, reducing their volume for easier handling and transport. Compacting waste not only saves space but also enhances efficiency in projects. However, choosing the right compactor can be daunting.

Various types exist, each with specific features and uses. Contractors often face challenges in narrowing down options. Whether it’s a soil compactor or a trash compactor, each type serves distinct purposes. It’s essential to understand the differences and functionalities to make a wise investment. Many overlook the importance of understanding their project needs before buying. This oversight can lead to inefficiencies and increased costs.

When selecting a Compactor Machine, one must consider factors such as weight, power, and intended application. Not every type will suit every situation. Evaluating your requirements is vital to ensure effectiveness. Compacting materials improperly can result in wasted resources and time. Awareness of these details will guide you in making informed decisions for your projects.

Overview of Compactor Machines and Their Significance

Compactor machines play a vital role in construction and waste management. They help reduce volume and improve compaction efficiency. Whether it’s soil, asphalt, or debris, these machines make the job easier. Each type serves unique purposes. For instance, vibratory compactors excel in soil applications, while static plate compactors are perfect for asphalt.

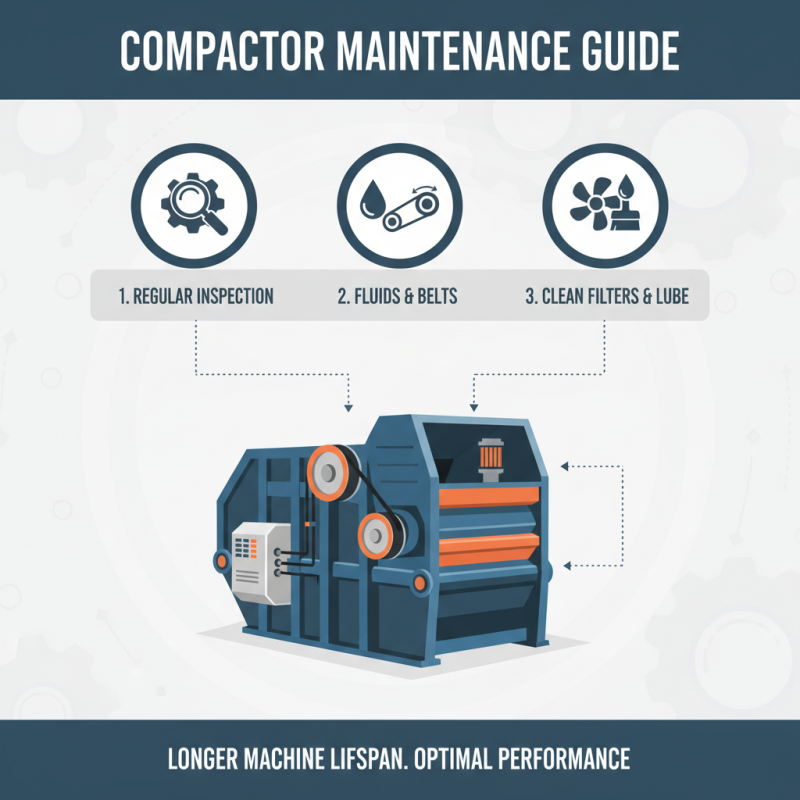

Understanding the significance of these machines can guide better purchasing decisions. Compactors save time and resources. They also ensure stability and longevity of the structures built. Many users overlook maintenance needs. Neglecting regular checks may lead to equipment failure. This can disrupt projects and increase costs.

Moreover, the choice of the right compactor depends on the job at hand. Misjudging the right type can result in ineffective compaction. Potential buyers should research different models and their features. It's essential to match the compactor’s capabilities with project requirements. Engaging with expert opinions might provide invaluable insights.

Key Features to Consider When Buying a Compactor Machine

When selecting a compactor machine, key features are crucial. You should consider the type of compaction required for your project. According to industry reports, vibratory compactors are the most widely used, especially in road construction. Their ability to achieve high density in soil and asphalt makes them popular. It is notable that around 40% of projects can benefit significantly from this type of compaction.

Weight and size matter, too. Lighter models are easier to maneuver, but heavier machines provide deeper compaction. A recent survey indicated that 65% of contractors prefer machines that balance portability with power. Additionally, the fuel efficiency of the compactor is important. A more efficient machine can save up to 30% in fuel costs over time. Brands often neglect energy consumption when promoting machines.

Another critical feature is ease of maintenance. Compactors with accessible parts will reduce downtime. Research shows that frequent maintenance can enhance machine lifespan by 20%. Operators need to reflect on these factors carefully. Sometimes, a machine might seem perfect on paper but may not fit real-world needs. Evaluate your project requirements thoroughly. Don't rush your decision. Each feature you overlook can lead to costly mistakes later on.

Top 10 Compactor Machines: Weight Comparison

Top 10 Compactor Machines: Reviews and Comparisons

When choosing a compactor machine, the options can be overwhelming. Compacting materials is crucial for construction, landscaping, and more. Users need reliable machinery to handle soil, asphalt, and debris. Weight and mechanism matter greatly.

Vibratory compactors, for example, provide better results for loose materials.

Consider your specific needs. A heavier machine isn’t always better. For small projects, a lighter model may suffice. Evaluate the surface you'll work on. Some compactors work best on flat terrain, while others can manage uneven surfaces effectively. Also, think about the ease of transportation. A bulky machine can be cumbersome.

Tips: Always check the user reviews. You’ll find real-world insights that can influence your decision. Compare performance based on tasks. Are there complaints about durability? Pay attention. A slight flaw can lead to big delays.

In the end, reflect on your budget too. Sometimes, spending more upfront can save money over time. Make informed choices for better results.

Home

About Us

products

Resource

Blog

Contact Us

Internal Vibrator

Internal Vibrator

External Vibrator

External Vibrator

Submersible Pump

Submersible Pump

Eccentric shaft

Eccentric shaft

Pendulum shaft

Pendulum shaft

Portable vbrator shaft

Portable vbrator shaft

Portable concrete mixer

Portable concrete mixer

Vertical concrete mixer

Vertical concrete mixer

Hydraulic concrete mixer

Hydraulic concrete mixer

Walk behind power trowel

Walk behind power trowel

Ride on power trowel

Ride on power trowel

Concrete screed

Concrete screed

Tamping rammer

Tamping rammer

Plate compactor

Plate compactor

Vibratory roller

Vibratory roller