Top 10 Tips for Choosing the Best Plate Compactor for Your Projects

When it comes to construction and landscaping projects, a reliable Plate Compactor can be an indispensable tool for achieving a smooth and solid surface. Whether you are preparing a foundation, laying down pavers, or working with asphalt, the right compactor can significantly enhance the efficiency and quality of your work. However, with a multitude of options on the market, selecting the best Plate Compactor for your specific needs can be a daunting task.

In this guide, we will explore the top ten tips that can help you navigate the process of choosing the perfect Plate Compactor. From considering the type of projects you'll be undertaking to understanding the various features and specifications of different models, our insights will equip you with the knowledge to make an informed decision. By evaluating your requirements and weighing the pros and cons of each option, you can ensure that you invest in a Plate Compactor that not only meets your expectations but also enhances the overall efficiency of your projects.

Understanding Plate Compactors: Types and Their Applications

When selecting the best plate compactor for your projects, it’s essential to understand the different types available and their specific applications. Plate compactors generally fall into two categories: forward plate compactors and reversible plate compactors. Forward plate compactors are designed for efficient soil compaction in linear applications, making them ideal for road construction and paving projects. In contrast, reversible plate compactors offer versatility with their ability to compact both forward and backward, which is valuable for working in confined spaces.

One key tip when choosing a plate compactor is to consider the weight and size of the machine, as these factors directly influence its compaction performance. Heavier compactors provide greater force, suitable for more extensive projects, while lighter models are easier to maneuver for small-scale applications. Additionally, ensure that the compactor's plate width aligns with the area you plan to compact, as this will affect the efficiency of your work.

Another crucial aspect is the machine's vibration frequency, which can impact both the compaction speed and the final density of the soil. Higher frequencies tend to work faster and are efficient on granular soils, whereas lower frequencies are better suited for cohesive soils. By understanding these distinctions, you can select a plate compactor that best fits the needs of your project while optimizing performance and outcomes.

Key Specifications: What to Look for in Plate Compactor Performance

When selecting the best plate compactor for your projects, understanding key specifications is critical for ensuring optimal performance. One of the primary aspects to consider is the compactor's weight. Heavier models generally provide deeper compaction, making them suitable for dense materials like gravel and soil. Conversely, lighter models are easier to maneuver and perfect for smaller tasks, such as sand and loose materials. Additionally, the plate size affects the machine's efficiency; larger plates can cover more area but may require more power.

Another essential specification to assess is the compaction force, often measured in pounds per square inch (PSI). A higher PSI indicates stronger compaction, which is necessary for working on tough surfaces. Furthermore, the engine power (usually in horsepower) plays a significant role in performance; a robust engine ensures that the compactor can efficiently handle prolonged use and tougher jobs without overheating. Lastly, consider the vibration frequency, as it affects both the compaction effectiveness and operator comfort during extended usage. Prioritizing these specifications will help you choose a plate compactor that meets your project requirements.

Weight Considerations: How Machine Weight Affects Compaction Efficiency

When selecting the best plate compactor for your projects, one of the critical factors to consider is the weight of the machine. The weight directly influences compaction efficiency, as heavier machines typically exert more force on the surface material, resulting in better compaction. According to a report by the American National Standards Institute (ANSI), compactors weighing between 1,500 to 2,000 pounds are ideal for heavy-duty tasks, such as compacting dense soils and asphalt. This weight range helps achieve a minimum compaction depth of up to 12 inches, ensuring a solid foundation for construction projects.

Moreover, the type of project often dictates the required weight of the compactor. For residential landscaping or smaller applications, lightweight compactors (around 100 to 300 pounds) may suffice, providing adequate compaction for granular soils and base materials. A study by the International Society for Soil Mechanics and Geotechnical Engineering (ISSMGE) indicates that lightweight models are effective for surface layer compaction, with an average increase of 80% in density observed within the top few inches of soil. Therefore, understanding the relationship between machine weight and compaction performance is vital for selecting the right plate compactor tailored to specific project needs.

Top 10 Tips for Choosing the Best Plate Compactor for Your Projects

| Weight Category (lbs) |

Compaction Depth (inches) |

Recommended Applications |

Vibration Frequency (Hz) |

Compaction Force (lbs) |

| 100 - 150 |

4 - 6 |

Asphalt and asphalt repair |

4000 |

3000 |

| 150 - 250 |

6 - 10 |

Granular soils, gravel |

4000 |

5000 |

| 250 - 350 |

10 - 12 |

Base preparation for concrete |

3500 |

7000 |

| 350 - 450 |

12 - 16 |

Heavy-duty compaction |

3000 |

8000 |

| 450+ |

16+ |

Industrial applications |

2500 |

10000+ |

Engine Power and Fuel Type: Choosing for Optimal Performance and Economy

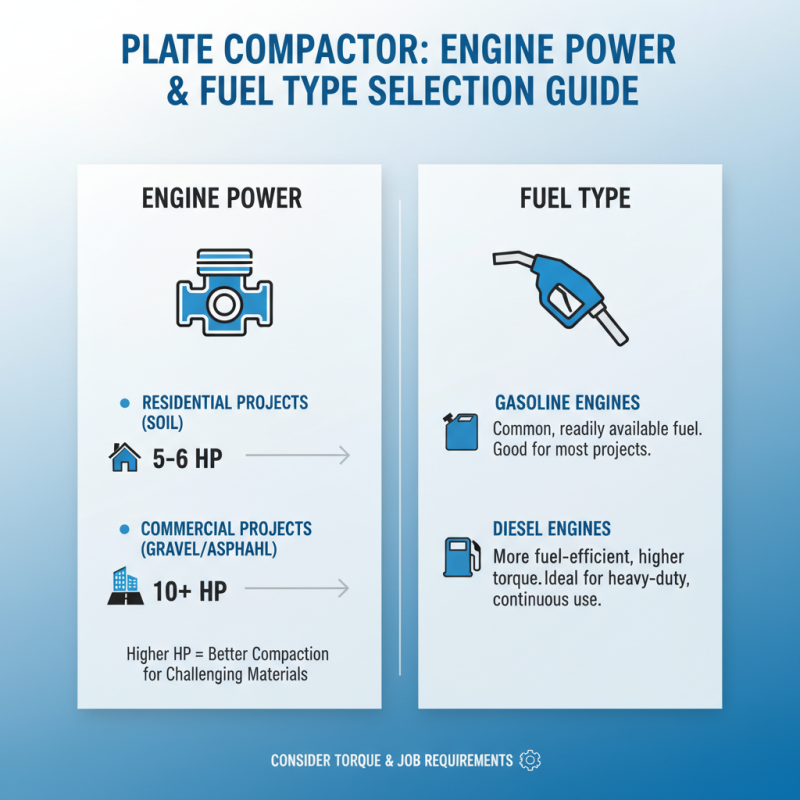

When selecting a plate compactor for your construction projects, one of the most critical factors to consider is the engine power and fuel type. According to industry reports, compactor performance is heavily influenced by the engine's horsepower and torque, which directly impacts the machine's ability to compact different soil types. For example, a model with at least 5 to 6 horsepower is typically recommended for residential projects, while larger commercial tasks may require engines that deliver upwards of 10 horsepower to handle more challenging materials like gravel or asphalt effectively.

Fuel type also plays a vital role in determining a plate compactor's efficiency and operational costs. Gasoline-powered compactors are generally favored for their portability and power, making them ideal for small to medium jobs that require frequent movement. On the other hand, diesel models, while often more expensive upfront, can provide higher fuel efficiency and lower running costs over time, especially for heavy-duty applications. A market analysis by EquipmentWatch indicates that diesel compactors can deliver a 20-30% higher fuel efficiency compared to their gasoline counterparts, translating to substantial savings in long-term project budgets. Therefore, carefully evaluating engine power and fuel type will not only optimize performance but also enhance economic viability for your specific project needs.

Safety Features: Essential Aspects for Operator Protection in Construction Equipment

When selecting the best plate compactor for your construction projects, one crucial aspect to consider is safety features. These machines can exert significant force, making it essential to prioritize operator protection. Look for models that come equipped with safety handles designed to reduce vibration, ensuring a comfortable grip and minimizing the risk of operator fatigue. Additionally, some compactors feature emergency stop buttons that provide quick access to shut off the machine in hazardous situations.

Another important safety aspect is the stability of the compactor itself. Choose a model with a low center of gravity, which helps prevent tipping during operation. Furthermore, consider machines with protective frames that shield the operator from potential debris and offer enhanced durability. Regular maintenance of the compactor also plays a role in safety, as it ensures that all components, including safety features, are functioning correctly.

As you explore your options, keep these tips in mind: Always check for integrated safety features, look for user-friendly designs that promote better control, and when possible, opt for models with additional safety certifications. By focusing on these factors, you can select a plate compactor that not only meets your project needs but also prioritizes the safety and well-being of the operator.

Home

About Us

products

Resource

Blog

Contact Us

Internal Vibrator

Internal Vibrator

External Vibrator

External Vibrator

Submersible Pump

Submersible Pump

Eccentric shaft

Eccentric shaft

Pendulum shaft

Pendulum shaft

Portable vbrator shaft

Portable vbrator shaft

Portable concrete mixer

Portable concrete mixer

Vertical concrete mixer

Vertical concrete mixer

Hydraulic concrete mixer

Hydraulic concrete mixer

Walk behind power trowel

Walk behind power trowel

Ride on power trowel

Ride on power trowel

Concrete screed

Concrete screed

Tamping rammer

Tamping rammer

Plate compactor

Plate compactor

Vibratory roller

Vibratory roller