What is a Reversible Compactor and How Does it Work?

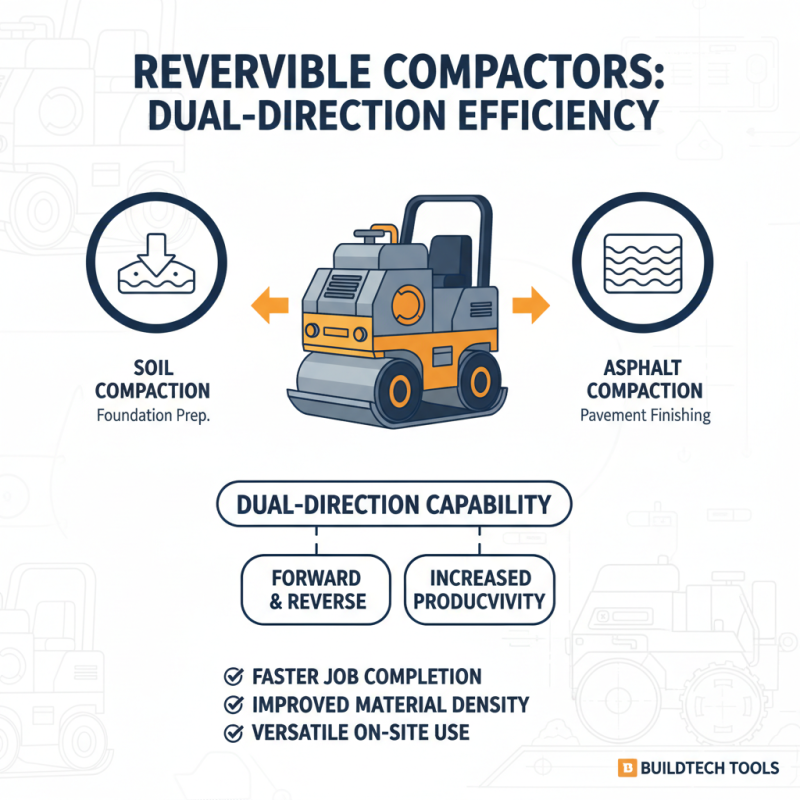

In the world of construction and landscaping, understanding machinery is essential. The Reversible Compactor is a key player in this field. Experts like John Anderson, a leading industry specialist, emphasize its importance, stating, "A Reversible Compactor can enhance efficiency on any job site." This powerful machine is primarily designed to compact soil, gravel, or asphalt.

What sets the Reversible Compactor apart is its unique ability to move in both forward and reverse directions, which greatly improves maneuverability. This feature is crucial when working in tight spaces. Operators appreciate how it simplifies the compaction process, reducing labor and time on projects. However, there are challenges. Misuse can lead to uneven surfaces or damage to materials.

Understanding the mechanics of a Reversible Compactor is vital for safety and efficiency. Operators must be trained to handle these machines properly. A lack of knowledge can lead to accidents or costly errors. Hence, continuous learning in this domain is encouraged. The importance of the Reversible Compactor cannot be overstated in modern construction practices.

What is a Reversible Compactor?

A reversible compactor is a powerful piece of equipment used mainly for soil and asphalt compaction. Its unique design allows it to move forward and backward, making it versatile for different types of jobs. This dual-motion capability is particularly useful in tight spaces where maneuverability is essential. The operator can control the direction easily, improving efficiency on job sites.

The working mechanism of a reversible compactor is fascinating. It typically features a flat base with heavy weight on top. As the base vibrates, it compacts the ground, removing air pockets and increasing density. The vibrations help to settle the material firmly. Moreover, the ability to reverse allows for a more thorough compaction in one pass. It achieves better results compared to standard compactors, but proper training is crucial for safety and effectiveness.

Using a reversible compactor demands skill. The operator must adjust pressure and speed based on the material type. Too much pressure can damage the surface, while not enough may leave it loose. Mistakes can lead to uneven surfaces. Continuous practice is necessary to become proficient, as each job presents unique challenges. This equipment can be a great asset if used correctly.

Key Features of Reversible Compactors

Reversible compactors are vital tools in construction. They are designed to compact soil and asphalt effectively. These machines come with unique features that enhance their performance. One notable aspect is their dual-direction capability. This allows operators to compact materials in both forward and reverse, increasing efficiency on the job site.

The vibratory plates of reversible compactors play a significant role in their functionality. These plates produce vibrations that help to settle materials tightly. This is crucial for creating stable foundations. Additionally, their adjustable frequency settings cater to various surface types. However, choosing the right setting needs careful consideration. An incorrect frequency can lead to insufficient compaction or surface damage.

Another important feature is their compact size, making them maneuverable in tight spaces. They are often lightweight, which aids in transportation. Yet, this lightweight design can sometimes affect performance on highly compacted surfaces. Operators must remain vigilant and adapt their techniques accordingly. Proper handling and understanding of the machine's limits are key to achieving optimal results.

How Reversible Compactors Operate

Reversible compactors are essential for various construction projects. They operate through two key functions: forward and reverse. This dual-direction operation allows for efficient soil compaction in tight spaces.

When driving forward, the machine exerts downward pressure, compressing the material beneath it. In reverse, it ensures an even and thorough compaction, particularly in areas that are hard to reach.

The mechanism relies on heavy plates that vibrate rapidly. This vibration helps to break up and compact the soil more effectively than static methods. The weight of the compactor further aids in achieving the desired density. Operators must be attentive. Misjudging the compaction timing can lead to uneven surfaces. Each pass should be carefully calculated to ensure uniform results.

Despite their advantages, working with reversible compactors can be tricky. Operators must be skilled to avoid damaging existing structures. Visibility is often limited, making it difficult to gauge close proximity. Regular maintenance is necessary for optimal performance. A neglected machine may falter under heavy use, resulting in compromised work quality. Proper training and practice can mitigate these risks and enhance efficiency.

Applications of Reversible Compactors in Construction

Reversible compactors are vital in construction. They are designed to compact soil, gravel, and asphalt. These machines have a dual-motion feature, allowing them to move forward and backward. This ability enhances their efficiency in small areas. Their compact shape makes them ideal for various sites, from road projects to landscaping.

In construction, reversible compactors are often used for backfilling trenches. Their unique design enables operators to maneuver them with ease. This is especially true in tight spaces where larger equipment cannot access. Additionally, they provide better compaction, reducing the risk of future settling. The operator can adjust the speed based on the material type. However, sometimes it may take time to master this adjustment.

Using reversible compactors comes with challenges. Operators must ensure they apply consistent pressure. Inconsistent pressure may lead to uneven surfaces, which can cause delays, increasing project costs. It’s crucial for operators to practice and learn from experiences. Feedback from supervisors is essential for improvement. With time and attention, the advantages of reversible compactors can be fully realized in construction projects.

Maintenance Tips for Reversible Compactors

Reversible compactors are essential in construction and landscaping. They help compact soil and asphalt efficiently. However, regular maintenance is crucial to ensure optimal performance and longevity.

Keep the engine clean. Dirty engines can overheat and affect productivity. Follow the manufacturer's guidelines for oil changes. This is critical for the machine's health. Checking the air filter is also important. A clogged filter can hinder airflow and reduce power.

Check the plate for cracks. Even minor damage can lead to larger issues. Inspecting the drive system regularly is key. Listen for unusual sounds during operation. Addressing small problems early can prevent bigger breakdowns later. Scheduling maintenance can extend the life of the compactor significantly.

Experience shows that well-maintained equipment can last up to 50% longer than neglected machines. Neglecting small details can lead to costly repairs. Be proactive to keep your reversible compactor running smoothly.

Maintenance Frequency for Reversible Compactors

Home

About Us

products

Resource

Blog

Contact Us

Internal Vibrator

Internal Vibrator

External Vibrator

External Vibrator

Submersible Pump

Submersible Pump

Eccentric shaft

Eccentric shaft

Pendulum shaft

Pendulum shaft

Portable vbrator shaft

Portable vbrator shaft

Portable concrete mixer

Portable concrete mixer

Vertical concrete mixer

Vertical concrete mixer

Hydraulic concrete mixer

Hydraulic concrete mixer

Walk behind power trowel

Walk behind power trowel

Ride on power trowel

Ride on power trowel

Concrete screed

Concrete screed

Tamping rammer

Tamping rammer

Plate compactor

Plate compactor

Vibratory roller

Vibratory roller