Top 10 Diesel Concrete Vibrators for Efficient Construction Projects

In the realm of construction, efficiency and effectiveness are paramount to successfully completing projects on time and within budget. One essential tool that has gained popularity among construction professionals is the Diesel Concrete Vibrator. These powerful machines are designed to optimize the consolidation process of concrete, ensuring maximum strength and durability of structures. By eliminating air pockets and promoting better flow, Diesel Concrete Vibrators enhance the overall quality of concrete placements, making them a vital asset for both small-scale and large construction endeavors.

As the demand for robust and reliable construction equipment continues to rise, choosing the right Diesel Concrete Vibrator becomes crucial. With numerous options available on the market, it can be challenging for professionals to determine which models provide the best performance and value. This article aims to guide readers through the top 10 Diesel Concrete Vibrators that stand out for their efficiency, reliability, and ease of use. By focusing on these top selections, construction managers and workers alike can make informed decisions that will ultimately lead to successful project outcomes.

Top Features to Look for in Diesel Concrete Vibrators

When choosing a diesel concrete vibrator for construction projects, several key features should be prioritized to ensure efficiency and effectiveness. One of the most crucial aspects is power output. The engine's horsepower plays a significant role in determining how well the vibrator can handle different types of concrete mixes. A higher power output typically allows for deeper penetration into the concrete, leading to better compaction and fewer air bubbles. Additionally, an adjustable throttle can enhance versatility, allowing operators to tailor the vibration intensity based on specific job requirements.

Another important feature is the portability and weight of the diesel concrete vibrator. Construction sites often require equipment that can be easily moved from one location to another, especially in challenging terrain. A lightweight design or the inclusion of wheels can greatly improve mobility. Furthermore, durability is essential; the vibrator should be constructed from robust materials to withstand harsh conditions and heavy usage without compromising performance. Lastly, ease of maintenance cannot be overlooked. Access to critical components for regular servicing will prolong the life of the equipment and ensure consistent operational efficiency.

Comparison of Diesel vs. Electric Concrete Vibrators in Efficiency

When comparing diesel and electric concrete vibrators, efficiency emerges as a crucial factor in influencing project outcomes. Diesel vibrators are often favored for their immense power and operational endurance, especially in large-scale construction sites where electricity access may be limited. This makes them ideal for extensive pouring tasks, as they can maintain effective vibration for longer periods, ensuring uniform concrete consolidation. Their portability provides an added advantage in rugged terrains or remote locations.

On the other hand, electric concrete vibrators excel in smaller, more controlled environments, such as residential projects. They operate quietly, making them suitable for urban areas where noise restrictions are in place. Additionally, electric models are generally easier to maintain and operate, with lower emissions compared to their diesel counterparts. This focus on sustainability can be a significant advantage in project planning and execution.

Tips: When choosing between diesel and electric vibrators, consider the size and location of your project. For heavy-duty tasks in challenging environments, diesel options may prove more efficient. However, for smaller jobs, electric vibrators can provide the necessary performance while being easier to handle. Always ensure you assess the power source availability and environmental impact before making your choice.

Key Brands Leading the Diesel Concrete Vibrator Market

The diesel concrete vibrator market is characterized by several key brands that have established a reputation for delivering high-quality and reliable products. These brands are recognized for their innovative designs and robust technologies, ensuring optimal performance in demanding construction environments. Their commitment to quality and efficiency has made them leaders in the market, catering to the needs of construction professionals looking for durability and effectiveness in their tools.

These leading brands focus on user-friendly features and powerful engines that enhance the vibratory process, allowing for better consolidation of concrete. They often implement cutting-edge technology to minimize fuel consumption while maximizing output, which not only benefits the construction project but also supports sustainable practices. With an emphasis on customer feedback, these companies continuously improve their products, ensuring they meet the evolving demands of construction projects worldwide. This proactive approach helps them maintain their competitive edge in a dynamic and challenging market.

Top 10 Diesel Concrete Vibrators for Efficient Construction Projects

| Model |

Power (HP) |

Weight (lbs) |

Vibration Frequency (Hz) |

Fuel Tank Capacity (L) |

Price ($) |

| Model A |

10 |

150 |

50 |

5 |

3200 |

| Model B |

12 |

160 |

55 |

6 |

3600 |

| Model C |

8 |

140 |

48 |

4.5 |

2900 |

| Model D |

15 |

170 |

60 |

7 |

4000 |

| Model E |

9 |

155 |

47 |

5.5 |

3100 |

| Model F |

11 |

165 |

51 |

6.5 |

3300 |

| Model G |

10.5 |

145 |

49 |

5 |

3050 |

| Model H |

14 |

180 |

54 |

6.2 |

3700 |

| Model I |

13 |

175 |

53 |

7.5 |

3500 |

| Model J |

16 |

160 |

58 |

8 |

4200 |

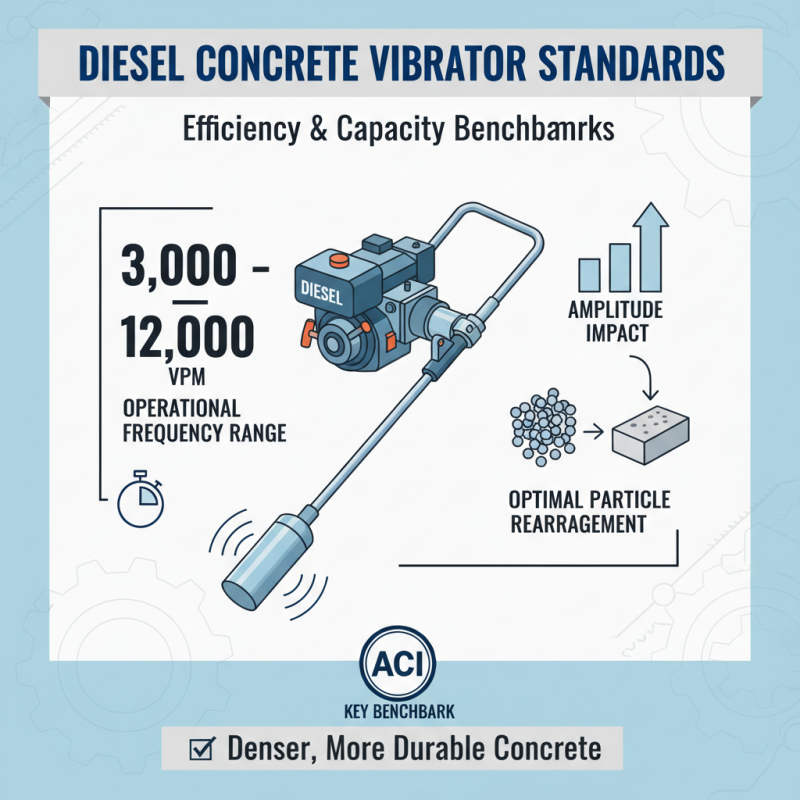

Industry Standards for Diesel Concrete Vibrators and Their Capacity

When discussing diesel concrete vibrators, it's crucial to highlight the industry standards that determine their efficiency and capacity. According to the American Concrete Institute (ACI), a key benchmark for vibrators is their frequency and amplitude, which directly impact the quality of concrete consolidation. Diesel concrete vibrators typically feature an operational frequency ranging from 3,000 to 12,000 vibrations per minute (VPM). Higher frequencies, coupled with adequate amplitude, facilitate optimal particle rearrangement within the concrete mix, ensuring a denser, more durable final product.

The capacity of diesel concrete vibrators is also influenced by the size of the engine and the design of the vibrator itself. Industry standards suggest that effective vibrators should develop a centrifugal force of at least 2,000 to 12,000 pounds. Reports from construction industry studies indicate that vibrators meeting or exceeding these specifications significantly reduce voids in the concrete, which can lead to structural weaknesses over time. Furthermore, complying with safety guidelines outlined in the Occupational Safety and Health Administration (OSHA) regulations is essential, as it ensures not only the operational efficiency of the equipment but also the safety of the workforce involved in construction projects. Ultimately, selecting diesel concrete vibrators that adhere to these industry standards is key to the success of any construction endeavor.

Impact of Vibrator Frequency on Concrete Compaction Quality

The frequency of the vibrator plays a critical role in achieving optimal concrete compaction quality. Higher frequencies can induce better consolidation of the concrete mix by creating rapid vibrations that penetrate deeply into the material. This agitation helps to eliminate air pockets and voids, ensuring that the mixture is dense and uniformly distributed. The effectiveness of the vibrator increases with the right frequency, as it enables the fine aggregates to settle while the coarser aggregates are properly aligned, resulting in enhanced structural integrity.

Moreover, the impact of vibrator frequency on compaction extends beyond just the immediate effect on the concrete. It influences the long-term durability and performance characteristics of the hardened concrete. Frequencies that are too low may lead to insufficient compaction, which can foster problems like cracking or erosion over time. Conversely, excessively high frequencies can cause segregation of the mix, leading to a weaker concrete structure. Therefore, understanding the ideal frequency range for different concrete types and construction conditions is crucial for ensuring that all aspects of compaction are effectively addressed, ultimately resulting in stronger, more durable constructions.

Top 10 Diesel Concrete Vibrators - Impact of Vibrator Frequency on Concrete Compaction Quality

Home

About Us

products

Resource

Blog

Contact Us

Internal Vibrator

Internal Vibrator

External Vibrator

External Vibrator

Submersible Pump

Submersible Pump

Eccentric shaft

Eccentric shaft

Pendulum shaft

Pendulum shaft

Portable vbrator shaft

Portable vbrator shaft

Portable concrete mixer

Portable concrete mixer

Vertical concrete mixer

Vertical concrete mixer

Hydraulic concrete mixer

Hydraulic concrete mixer

Walk behind power trowel

Walk behind power trowel

Ride on power trowel

Ride on power trowel

Concrete screed

Concrete screed

Tamping rammer

Tamping rammer

Plate compactor

Plate compactor

Vibratory roller

Vibratory roller