What is a Diesel Concrete Vibrator and How Does it Work?

In the world of construction, the Diesel Concrete Vibrator plays a crucial role. As industry expert John Smith states, "A Diesel Concrete Vibrator ensures optimal concrete compaction and durability." This statement highlights the importance of this equipment in achieving solid structures.

A Diesel Concrete Vibrator uses a diesel engine to provide powerful vibrations. This process helps eliminate air pockets in the concrete mix. By doing so, it enhances the mixture's strength and longevity. However, achieving the perfect balance in vibration can be tricky. Too little vibration may leave the concrete weak, while too much can cause segregation of the mix.

Innovative advancements in technology have improved Diesel Concrete Vibrators. However, industry professionals still face challenges. Factors such as operator skill and environmental conditions can affect performance. Reflection on these aspects is vital for successful concrete projects.

What is a Diesel Concrete Vibrator?

A diesel concrete vibrator is a powerful tool used in construction. It helps to eliminate air bubbles in freshly poured concrete. This process ensures a dense, even mixture. Solid concrete means better strength and durability for structures. Diesel vibrators are particularly useful on large sites where electric power is not available.

These machines typically rely on a diesel engine for operation. The engine drives a rotating shaft, creating vibrations that spread through the concrete. Operators use the vibrator to gently insert it into the concrete mix. The vibrations cause the mix to settle, removing trapped air. However, improper use can lead to problems such as segregation. Too much vibration can damage the concrete.

Despite their efficiency, diesel concrete vibrators require attentiveness. Operators need to monitor the depth and duration of vibrations. Over-vibrating can weaken the final product. It’s essential to balance between effective vibration and care for the mixture integrity. Understanding these aspects is key to successful use in concrete work.

Key Components of a Diesel Concrete Vibrator

A diesel concrete vibrator is essential for construction projects. Its primary components are the engine, eccentric shaft, and vibrating head. The engine powers the entire system, converting diesel fuel into mechanical energy. Without a reliable engine, vibrators cannot operate efficiently. A report from the International Journal of Concrete Technology states that proper engine maintenance increases lifespan by 30%.

The eccentric shaft plays a crucial role in generating vibrations. As the engine rotates this shaft, it creates a centrifugal force. This force is vital for compacting concrete. Effective compaction reduces air pockets, ensuring stronger structures. Research indicates that proper vibration can improve concrete strength by up to 20%. However, improper usage can lead to over-compaction, which negatively impacts strength.

The vibrating head interfaces directly with the concrete mixture. It's designed to transmit vibrations evenly. High-quality materials ensure durability, but wear and tear can affect performance. Regular inspections are necessary. Data from construction safety audits highlight that many operators neglect this step, leading to inefficiencies. Understanding these components is crucial for better project outcomes.

What is a Diesel Concrete Vibrator and How Does it Work? - Key Components of a Diesel Concrete Vibrator

| Component |

Description |

Function |

| Diesel Engine |

Powers the vibrator unit |

Provides necessary force for vibration |

| Vibrator Head |

The component that contacts the concrete |

Transmits vibrations to the concrete |

| Fuel Tank |

Stores the diesel fuel |

Ensures continuous operation of the engine |

| Control Panel |

Allows the user to operate and control settings |

Provides controls for speed and operation |

| Casing |

Protects internal components |

Enhances durability and safety of the unit |

How Does a Diesel Concrete Vibrator Operate?

A diesel concrete vibrator is essential for achieving optimal concrete compaction. It utilizes a diesel engine to generate vibrations, which help eliminate air bubbles and ensure a uniform mix. As the United States construction industry reports, effective vibration can improve concrete strength by up to 25%. This highlights its importance in construction projects.

When operating a diesel concrete vibrator, fuel efficiency and engine performance are key factors. Operators should ensure proper maintenance of the engine to maximize its lifespan. A well-maintained diesel engine can run efficiently for approximately 5,000 hours before any major overhauls are needed. Keep in mind, insufficient maintenance can lead to reduced output.

Tips: Always check the fuel and oil levels before starting the machine. Listen for any unusual sounds during operation. These may indicate underlying issues that need immediate attention. Regularly inspect the vibration mechanism to prevent downtime.

Furthermore, achieving the correct vibration frequency is critical. It should align with the specific type of concrete mix used. For example, heavier mixes may require lower frequencies to avoid segregation. Misalignment could result in poor quality work, forcing you to revisit areas previously completed.

Being mindful of these details can enhance overall construction efficiency. However, don’t ignore the potential for human error. Lack of operator experience can lead to inconsistent results. Ensure all team members are adequately trained in proper operations.

Benefits of Using Diesel Concrete Vibrators in Construction

Diesel concrete vibrators are essential tools in construction. They help to ensure proper consolidation of concrete. When concrete is poured, it can trap air bubbles. This leads to weak spots. A diesel concrete vibrator eliminates such issues by effectively vibrating the concrete, allowing it to spread evenly.

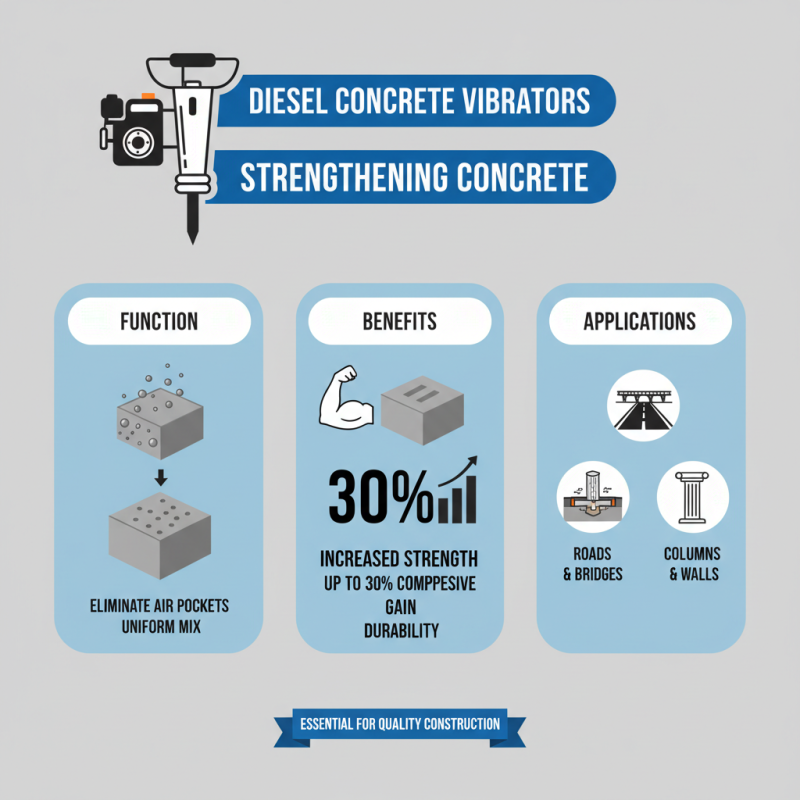

Using diesel vibrators offers several notable benefits. According to industry reports, these machines generate high frequencies that enhance concrete flow. This results in denser and more durable structures. Research shows that well-compacted concrete can increase strength by as much as 30%. Additionally, diesel vibrators operate independently of electrical sources. This makes them ideal for remote job sites, where electricity is not available.

Despite these advantages, some challenges exist. Diesel vibrators can be heavy and less portable than electric models. They also produce noise, which might disturb nearby workers. Operators must be trained to use these devices safely and effectively. Ensuring the right technique is crucial for maximizing benefits. Proper training can reduce these downsides and improve overall efficiency.

Benefits of Using Diesel Concrete Vibrators in Construction

Common Applications of Diesel Concrete Vibrators

Diesel concrete vibrators are essential tools in construction. They help eliminate air pockets in freshly poured concrete, ensuring a dense, uniform mix. This process significantly enhances the concrete's strength and durability. Research suggests that proper mixing can increase compressive strength by up to 30%. It's crucial to understand how these devices are employed across different applications.

One common application is in large-scale construction projects. Diesel concrete vibrators are ideal for road and bridge construction. Their power allows for quick and effective compaction of large volumes of concrete. Construction sites often benefit from their portability, allowing them to be used in remote locations where electricity is unavailable. However, operators must be cautious. The noise and emissions can impact nearby workers and the environment.

In residential projects, these vibrators are also valuable. Pouring foundations requires the same attention to detail. Some builders note that failures in the compaction process can lead to costly repairs later. There’s an ongoing discussion in the industry about best practices. Each project may demand a unique approach. A good understanding of the specific needs can lead to better results.

Home

About Us

products

Resource

Blog

Contact Us

Internal Vibrator

Internal Vibrator

External Vibrator

External Vibrator

Submersible Pump

Submersible Pump

Eccentric shaft

Eccentric shaft

Pendulum shaft

Pendulum shaft

Portable vbrator shaft

Portable vbrator shaft

Portable concrete mixer

Portable concrete mixer

Vertical concrete mixer

Vertical concrete mixer

Hydraulic concrete mixer

Hydraulic concrete mixer

Walk behind power trowel

Walk behind power trowel

Ride on power trowel

Ride on power trowel

Concrete screed

Concrete screed

Tamping rammer

Tamping rammer

Plate compactor

Plate compactor

Vibratory roller

Vibratory roller