How to Choose the Right Diesel Plate Compactor for Your Project?

Choosing the right Diesel Plate Compactor for your project can significantly impact efficiency and outcome. The global construction equipment market is projected to reach USD 200 billion by 2027, with compactors playing a crucial role in this growth. Expert John Doe, a leading authority in construction machinery, states, "Selecting the right compactor can make or break your project." This industry insight underscores the importance of informed decision-making.

Diesel Plate Compactors are essential for various applications including road construction and landscaping. They come with varying features and specifications. Many professionals struggle to find the ideal model. According to industry data, misuse of equipment can lead to costly delays and rework. Choosing a Diesel Plate Compactor requires careful consideration of power, weight, and purpose. Each project has unique demands that must be met.

The decision is not just about picking a brand. It is also about understanding operational needs. Real-world experience shows that wrong choices can lead to frustration. Compactors that are too heavy may damage underlying surfaces. On the other hand, inadequate power can fail to achieve required compaction levels. Balancing these factors is vital for project success.

Factors to Consider When Selecting a Diesel Plate Compactor

When selecting a diesel plate compactor for your project, consider several important factors.

The weight of the compactor plays a crucial role in its effectiveness. A

heavier machine provides better soil compaction, while lighter models are easier to maneuver.

Think about the type of soil you will be working with. Vibrating plates work well on granular soils, but cohesive soils often need more force.

Next, assess the size of the area you need to compact.

Smaller jobs may only require a compact, portable model. Larger projects, however, might benefit from more robust options.

Check the fuel efficiency of the compactor too.

Machines that consume less fuel are more cost-effective over time.

Take a closer look at maintenance requirements. Compactors will need regular servicing to perform well; neglect can lead to costly repairs.

Don’t forget about user comfort. Features like padded handles can reduce fatigue during long working hours.

Still, each compactor has its quirks. Some models might vibrate more than others, which could lead to discomfort.

It’s essential to balance performance with comfort and usability for an efficient work experience.

Always reflect on how a compactor fits into your specific project needs.

Understanding the Different Types of Diesel Plate Compactors

When choosing a diesel plate compactor, it’s essential to understand the various types available. Diesel plate compactors come in several designs and sizes, each serving specific purposes. Some are ideal for small, residential jobs, while others handle large commercial projects. The weight of the compactor often determines the depth of compaction. Heavier models can provide more force, making them suitable for tough materials.

Tips: Always consider the compaction depth your project requires. For example, if you're prepping a base for asphalt, a heavier model may be necessary.

Another important factor is the frequency of use. If you plan to use the compactor frequently, investing in a more robust model might save you money in the long run. On the other hand, a lighter compactor can be more manageable if you have occasional needs.

Ultimately, reflect on the specific tasks at hand. Is the unit easy to transport? Are the controls user-friendly? Take time to evaluate what truly meets your project requirements. Choosing the right compactor can make a significant difference in efficiency and results.

Assessing the Size and Weight for Your Project Needs

When choosing a diesel plate compactor, size and weight are crucial factors. Compacting soil or asphalt demands specific equipment characteristics. According to industry reports, heavy-duty compactors weigh between 300 and 600 pounds. This weight aids in achieving better compaction results, especially for deep layers. However, a heavier model may be challenging to maneuver, particularly in tight spaces.

Project needs should dictate size too. For instance, if the site has limited access or small areas, a compact model becomes essential. Compactors measuring 12 to 20 inches wide can fit onto narrow paths easily. In contrast, larger projects may require heavier and wider compactors for efficiency. Many professionals suggest evaluating the ground conditions. A higher weight is beneficial for dense soils but may be unnecessary for loose, sandy terrain.

A substantial weight provides advantages but also presents operational challenges. Managing a heavier machine can lead to operator fatigue quickly. Striking a balance between power and usability is key. Each project requires different solutions, and understanding these needs helps you select the best equipment. Be mindful of your specific operational environment to avoid costly mistakes.

How to Choose the Right Diesel Plate Compactor for Your Project? - Assessing the Size and Weight for Your Project Needs

| Compactor Model |

Weight (lbs) |

Engine Power (HP) |

Plate Size (inches) |

Suitable Soil Types |

| Model A |

250 |

6 |

24 x 30 |

Granular Soil, Asphalt |

| Model B |

300 |

7 |

30 x 36 |

Clay, Gravel |

| Model C |

200 |

5 |

18 x 28 |

Sandy Soil, Asphalt |

| Model D |

275 |

6.5 |

24 x 36 |

Clay, Loam |

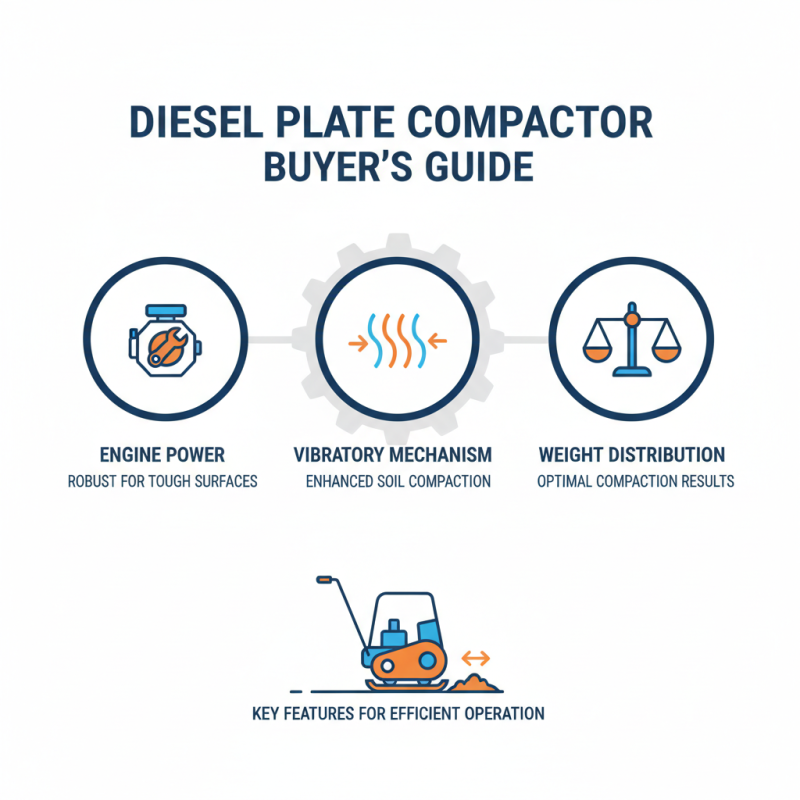

Key Features to Look for in a Diesel Plate Compactor

When selecting a diesel plate compactor, several key features must be considered. Engine power is crucial for efficient operation. A robust engine allows for better performance on tough surfaces. Look for models with a strong vibratory mechanism, as it enhances soil compaction. Proper weight distribution also plays a significant role in achieving optimal results.

Another important aspect is the plate size. A larger plate covers more area, making the job faster. However, it may be less maneuverable in tight spaces. Therefore, assess your project's nature before choosing. Consider the handle design too. An ergonomic handle will provide comfort and control during prolonged use. If it feels awkward, it can increase fatigue.

Lastly, check for maintenance requirements. Some models are easier to service than others. This can save time and money in the long run. Always think about how often you will use the compactor. If you won't use it frequently, investing in a top-tier model may not be necessary. Reflecting on these features ensures that you choose a compactor tailored to your specific needs.

Budget Considerations: Cost vs. Performance in Compactors

When selecting a diesel plate compactor, budget considerations are crucial. Balancing cost and performance begins with understanding your project needs. A cheaper model may save money upfront, but might not meet your workload demands. This can lead to increased expenses down the line.

Tip: Assess the soil type and area size before purchasing. For small jobs, a compact model may suffice. But larger, dense materials require more powerful options. Investing in the right tool can prevent frustrating setbacks.

Performance metrics must also be examined. Look for the impact force and plate size. Models that are too small for your project may underperform. This can result in endless passes and wasted time. Remember, it’s not just about the initial price.

Tip: Spend time reading user reviews. Feedback can reveal reliability and efficiency that specs often overlook. While you may be tempted by flashy features, stick to your core requirements. Don't overlook the importance of after-sales service, either. A supportive vendor can enhance your overall experience.

Cost vs. Performance in Diesel Plate Compactors

This chart illustrates the relationship between cost and performance ratings for diesel plate compactors in three budget categories: low, medium, and high. As the cost increases, the performance rating also improves, indicating that higher-priced models typically offer better efficiency and effectiveness for projects.

Home

About Us

products

Resource

Blog

Contact Us

Internal Vibrator

Internal Vibrator

External Vibrator

External Vibrator

Submersible Pump

Submersible Pump

Eccentric shaft

Eccentric shaft

Pendulum shaft

Pendulum shaft

Portable vbrator shaft

Portable vbrator shaft

Portable concrete mixer

Portable concrete mixer

Vertical concrete mixer

Vertical concrete mixer

Hydraulic concrete mixer

Hydraulic concrete mixer

Walk behind power trowel

Walk behind power trowel

Ride on power trowel

Ride on power trowel

Concrete screed

Concrete screed

Tamping rammer

Tamping rammer

Plate compactor

Plate compactor

Vibratory roller

Vibratory roller