2026 How to Choose the Right Cement Vibrator Needle for Your Needs?

Choosing the right Cement Vibrator Needle for your project can significantly impact the quality of your concrete work. A Cement Vibrator Needle is essential for achieving proper compaction in your mixes. Without the right needle, you may face issues like air pockets or uneven surfaces.

Different projects require different needle sizes and types. For instance, a construction project with heavy concrete may need a thicker needle for effective vibration. Conversely, smaller jobs may benefit from a more delicate needle, allowing for precision work. It’s not just about picking the first one you see. Understanding your specific requirements is key.

Reflect on your previous experiences. Have you chosen incorrectly in the past? How did that affect your project? Think about the length and diameter of the needle, as both play a role in your results. Selecting the proper Cement Vibrator Needle is crucial. The right choice can save you time, money, and frustration.

Factors to Consider When Selecting a Cement Vibrator Needle

Choosing the right cement vibrator needle can significantly impact your project. It’s essential to consider various factors. One major factor is the needle diameter. Larger diameters cover more area, while smaller ones are ideal for tight spaces. Think about the type of cement mix you will use. Thicker mixtures require more powerful needles.

Another important aspect is the length of the needle. Longer needles reach deeper than shorter ones. What is your project’s depth? Make sure the length matches your needs. Also, pay attention to the vibration frequency. Higher frequencies may work better for denser materials. But this can vary based on the specific job at hand.

Consider your comfort and usability as well. A heavy needle can be cumbersome. Test various weights to find what suits you. The vibration intensity should not be excessive but enough to eliminate air bubbles. Be prepared to experiment. Sometimes, the best choice is not immediately clear. It can take time to find the ideal needle for your unique requirements.

2026 How to Choose the Right Cement Vibrator Needle for Your Needs? - Factors to Consider When Selecting a Cement Vibrator Needle

| Needle Diameter (mm) |

Length (mm) |

Material |

Vibration Frequency (Hz) |

Weight (kg) |

Application Type |

| 25 |

1000 |

Steel |

120 |

2.5 |

Medium Duty |

| 30 |

1200 |

Stainless Steel |

135 |

3.0 |

Heavy Duty |

| 20 |

800 |

Aluminum |

110 |

2.0 |

Light Duty |

| 35 |

1500 |

Reinforced Steel |

140 |

3.5 |

Extra Heavy Duty |

Types of Cement Vibrator Needles Available in the Market

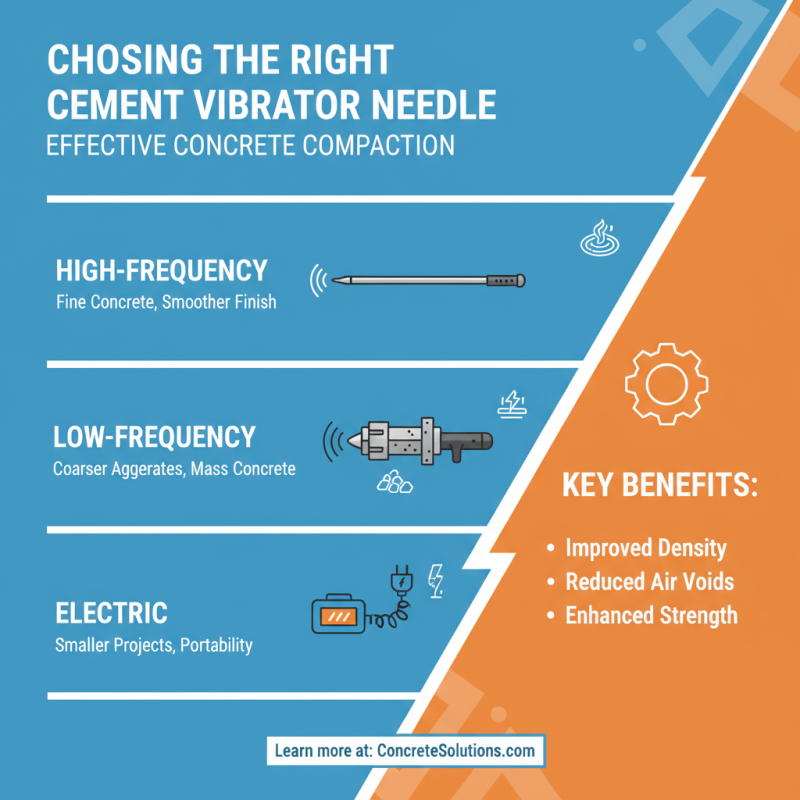

Choosing the right cement vibrator needle is crucial for effective concrete compaction. Various types of needles serve different purposes. You can find three main types: high-frequency, low-frequency, and electric needles, each with specific applications. High-frequency needles work better for fine concrete, while low-frequency versions are suitable for coarser aggregates. Electric needles often find use in smaller projects where portability matters.

Data from the construction industry indicates that using the appropriate needle can increase compaction efficiency by 50%. Selecting a needle based on project size can dramatically influence outcomes. For instance, a large-scale project may benefit from high-frequency needles, which provide greater vibration intensity. Meanwhile, smaller jobs might only require a simple, manual electric needle.

However, many professionals overlook the importance of length and diameter. A longer needle can reach deeper, ensuring comprehensive vibration in thicker concrete layers. While this is beneficial, it may lead to uneven compaction if not handled properly. Sometimes, operators underestimate the need for regular maintenance of these tools. Neglecting wear and tear can diminish effectiveness over time.

Diameter and Length: How They Affect Performance

When choosing a cement vibrator needle, diameter and length are crucial. A needle’s diameter impacts the ability to penetrate concrete. Wider needles agitate more material but may struggle in tighter spaces. Conversely, narrower needles reach deeper into compact areas. An effective choice can mean the difference between a smooth finish and a lumpy surface.

Length also plays a significant role in performance. Shorter needles may be more manageable for smaller projects. However, they may lack the reach necessary for extensive pours. Longer needles can cover more area but require more effort to maneuver. It's essential to find a balance that suits your specific project needs.

Consider these factors in relation to your working conditions. An incorrect choice can lead to wasted time and effort. It’s worth experimenting with different sizes to understand what works best. Reflect on past experiences with various needles and learn from any mistakes made. Performance varies; finding the right fit is often an iterative process.

2026 How to Choose the Right Cement Vibrator Needle for Your Needs?

This chart illustrates the impact of diameter and length on the performance of cement vibrator needles, helping you to make an informed decision.

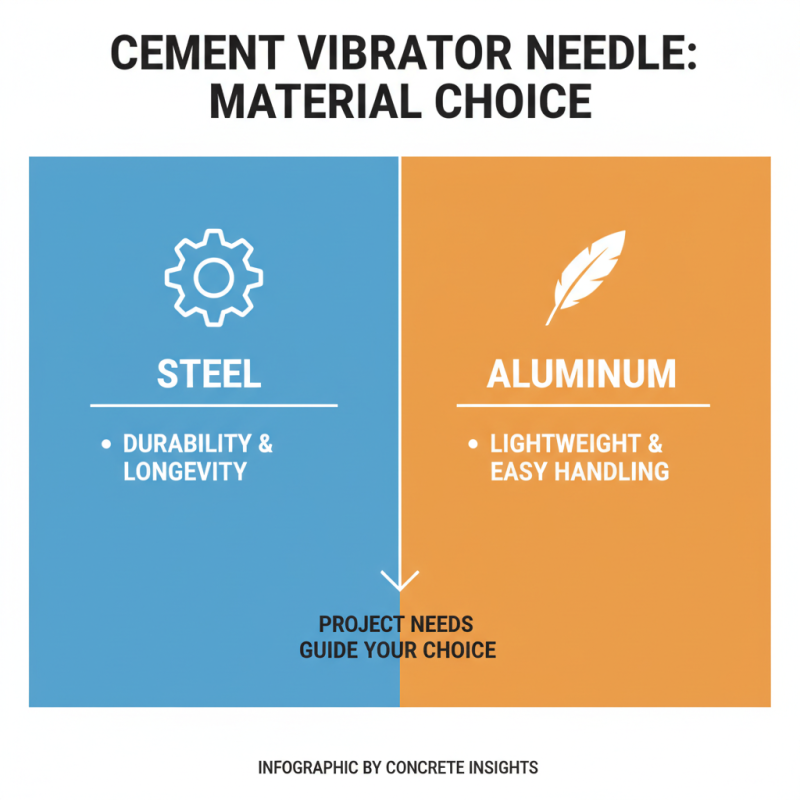

Material Choices for Durability and Effectiveness

When choosing a cement vibrator needle, material quality plays a crucial role. Both steel and aluminum are popular choices. Steel offers durability and longevity, while aluminum is lightweight and easier to handle. Understanding your project needs will guide your choice.

Tips: Test each material option before purchasing. Feel the weight and balance. It matters for prolonged use.

The effectiveness of a cement vibrator needle also hinges on its design. A smooth surface reduces friction, allowing for better performance. If the needle feels rough or uneven, reconsider your selection.

Tips: Consider the needle length for your specific application. Longer needles may reach deeper areas, but might be harder to manage.

Keep in mind that not all needles are created equal. Some may wear out faster than expected. Pay attention to usage frequency and the materials being worked with. A thoughtful selection ensures durability and job quality.

Compatibility with Your Equipment and Specific Projects

Choosing the right cement vibrator needle requires understanding compatibility with your equipment and specific projects. Many projects demand different types of needles to achieve optimal outcomes. For instance, a report by the American Concrete Institute indicates that a needle's diameter greatly influences compaction results. A 1-inch needle is ideal for small pours, while larger projects may require a 1.5-inch needle for efficiency.

When selecting a needle, ensure it fits your vibrator unit. Many machines only accept specific sizes or designs. Compatibility is key. Some users mistakenly purchase accessories that do not mount properly, leading to wasted time and resources. In 2022, equipment mismatches accounted for 25% of job delays in concrete projects, highlighting the need for careful selection.

Tip: Always check your equipment's manual for compatible needle sizes.

Another factor is project specifications. Different mixes react differently to vibration. A dry mix may need a more aggressive needle to avoid air pockets. In contrast, a wetter mix might require gentler vibrations. Effective vibration reduces voids and improves strength, often leading to a 15% increase in compressive strength, according to industry studies.

Tip: Test a needle on a small area before full-scale application to ensure effectiveness.

Remember, both equipment and project types influence your choice. Analyze your needs carefully to select the appropriate needle.

Home

About Us

products

Resource

Blog

Contact Us

Internal Vibrator

Internal Vibrator

External Vibrator

External Vibrator

Submersible Pump

Submersible Pump

Eccentric shaft

Eccentric shaft

Pendulum shaft

Pendulum shaft

Portable vbrator shaft

Portable vbrator shaft

Portable concrete mixer

Portable concrete mixer

Vertical concrete mixer

Vertical concrete mixer

Hydraulic concrete mixer

Hydraulic concrete mixer

Walk behind power trowel

Walk behind power trowel

Ride on power trowel

Ride on power trowel

Concrete screed

Concrete screed

Tamping rammer

Tamping rammer

Plate compactor

Plate compactor

Vibratory roller

Vibratory roller