2026 How to Choose the Best Plate Compactor for Your Needs?

When it comes to construction and landscaping projects, choosing the right Plate Compactor is crucial. According to industry reports, nearly 75% of compacting tasks require specific equipment to achieve optimal results. A Plate Compactor effectively compresses soil, gravel, and asphalt, ensuring a stable surface. However, not all compactors are created equal.

Selecting a Plate Compactor should align with your project's scale and soil type. For instance, lighter models suit small areas, while heavier ones are necessary for denser materials. Many users often underestimate the importance of the right size and weight. In fact, using the wrong Plate Compactor can lead to uneven surfaces and increased project costs.

It's essential to consider features such as frequency and force. Studies show that Plate Compactors with higher dynamic forces yield better results in difficult soil conditions. But making an informed choice isn't always easy. The market is flooded with options, and understanding specifications can be daunting. Making the right decision can highly impact your project's success and efficiency.

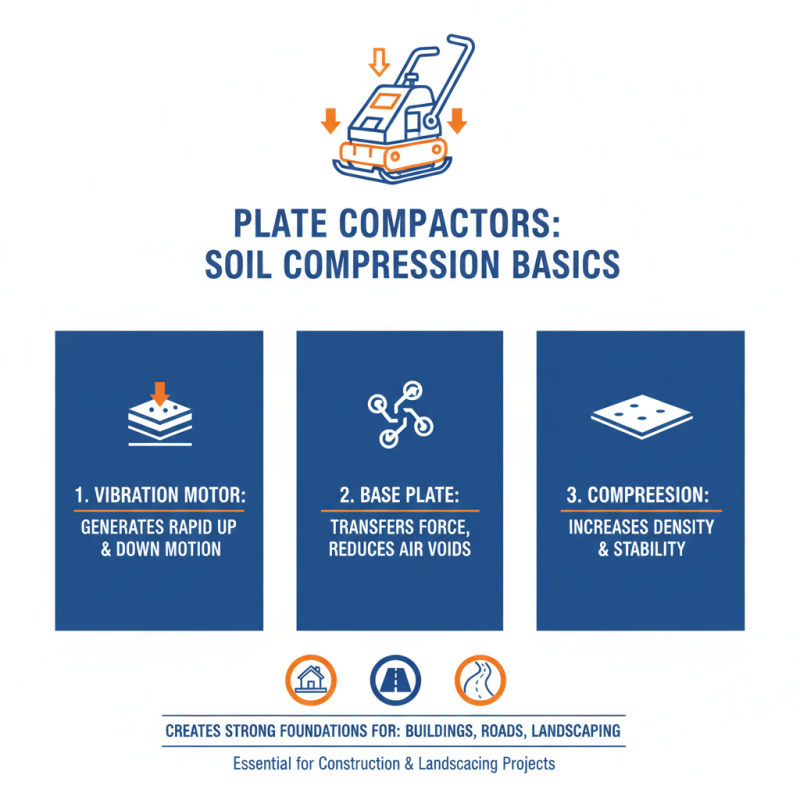

Understanding Plate Compactors: What They Are and How They Work

Plate compactors are essential tools for construction and landscaping. These machines help to compress soil, gravel, and asphalt. They are designed to provide a flat surface that is strong and stable. Understanding how they work can help you make better choices.

The mechanism of a plate compactor is fairly straightforward. It consists of a heavy plate that vibrates or oscillates. This vibration helps to compact the material beneath it by applying force. As the plate moves forward, it pushes down on the ground, eliminating air pockets and creating a solid foundation. The right choice can make a significant difference in your project.

**Tip:** Always consider the weight of the compactor. Heavier compactors exert more force and achieve deeper compaction. A lighter machine might be suitable for small jobs on softer soils. Assess the material type before renting or buying. Remember that compactors can be harder to handle. Practice is crucial. Understanding the limits of your machine can avoid issues.

**Tip:** Pay attention to how the compactor performs on your site. If it struggles or vibrates excessively, it may not be the right fit. Evaluate the surface before each task. Test compacting on a small area first. Adjustments can lead to better results. Be patient; the learning curve can be steep.

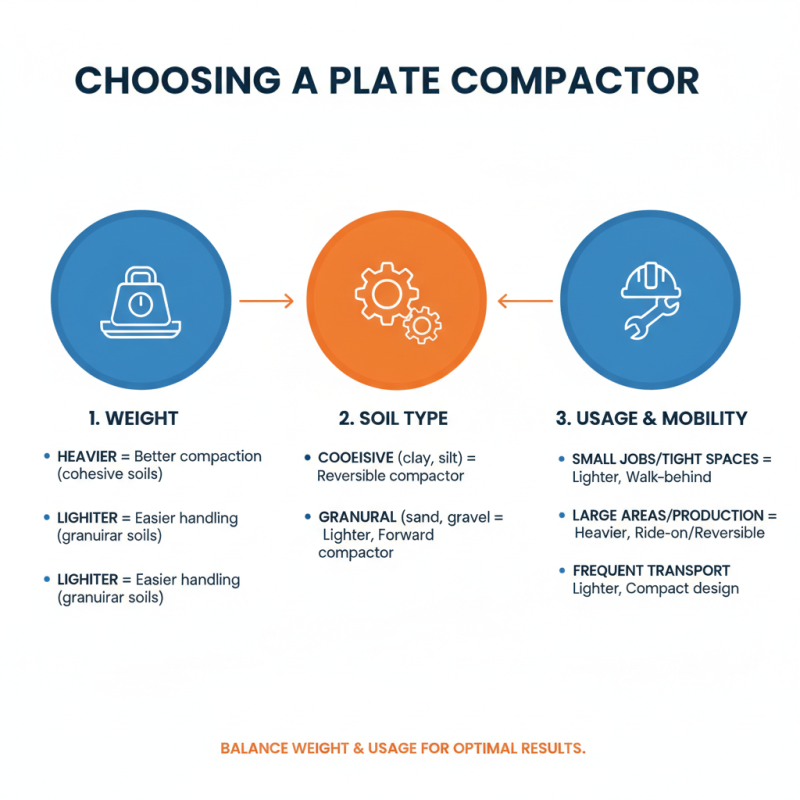

Key Factors to Consider When Choosing a Plate Compactor

Choosing the right plate compactor can be a daunting task. There are several key factors to consider in order to find the best option for your specific needs. The weight of the compactor plays a crucial role. Heavier models provide better compaction for difficult soil. However, a lighter machine is easier to maneuver. It’s important to balance weight and usage.

The plate size also matters significantly. A wider plate will cover more ground, making your work quicker. Yet, narrow plates excel in tight spaces. Consider your project’s requirements carefully. Are you working in restricted areas? A narrower model may be better.

Tips: Always check the vibration levels, too. High vibrations can cause fatigue over time. A comfortable handle will make your work easier. Lastly, think about maintenance. Some compactors require more care than others. Understand the upkeep needed before making your choice.

Types of Plate Compactors: Which One Suits Your Needs?

Choosing the right plate compactor can be challenging. Different types cater to specific needs. Understanding these types is crucial before making a decision.

There are several kinds of plate compactors. A light-duty model works well for small jobs. It’s suitable for sand, gravel, or asphalt. Medium-duty options can handle soil and more demanding tasks. Heavy-duty compactors are best for large-scale projects. They offer greater power and efficiency. Consider the weight and vibrations produced.

Tips: Think about the material you'll be working with. Match the compactor type to your project needs. Test its ease of use. A comfortable grip matters. Don't overlook maintenance. A well-maintained compactor lasts longer.

Some users find themselves overestimating their needs. Buying more power than necessary can lead to wasted resources. Others realize they need a lighter model for narrow areas. Reflect on your workspace constraints. Focus on how often you’ll use the compactor. This can influence your decision significantly.

2026: How to Choose the Best Plate Compactor for Your Needs?

Evaluating Engine Power and Weight for Optimal Performance

Selecting the right plate compactor is crucial. Engine power and weight significantly impact performance. A robust engine can deliver the force you need. Higher horsepower often translates to better efficiency on tougher surfaces. However, it’s essential to match engine power with the job requirements.

Weight also plays a vital role. Heavier compactors provide deeper compaction. They are ideal for dense materials like soil or asphalt. Yet, if your projects involve a lot of maneuvering, lighter models might be more suitable. It’s a balancing act. Too heavy, and you risk damaging weaker surfaces. Too light, and you may struggle to achieve optimal compaction.

Consider specific project needs. For small jobs, you might not need a heavy-duty model. Larger projects may demand greater engine power and weight. Take time to assess the terrain and materials before making a choice. It’s essential to test different options if you can. Each job is unique, and finding the right balance is key for achieving the best results.

2026 How to Choose the Best Plate Compactor for Your Needs?

| Model |

Engine Power (HP) |

Weight (lbs) |

Compaction Force (lbs) |

Plate Size (inches) |

| Model A |

5 |

150 |

3000 |

24 |

| Model B |

6.5 |

170 |

4000 |

30 |

| Model C |

4 |

140 |

2800 |

22 |

| Model D |

7 |

200 |

4500 |

36 |

Maintenance Tips for Long-lasting Plate Compactors

When using a plate compactor, maintenance is key for longevity. Regular upkeep ensures optimal performance and extends the tool’s life. One essential tip is to keep the compactor clean after each use. Dirt and debris can clog the engine and affect performance. Use a brush or compressed air to remove stubborn particles.

Another important aspect is checking fluid levels regularly. This includes the oil in the engine and any hydraulic fluid. Low levels can lead to mechanical failure over time. If you notice any leaks or stains, address them immediately.

Lastly, inspect the plates for any signs of wear and tear. Cracks or damage on the surface can disrupt the compaction process. Replacing worn plates in a timely manner prevents further issues. These simple actions can significantly improve the lifespan of your plate compactor. Regular maintenance may feel tedious, but it is worth the effort.

Home

About Us

products

Resource

Blog

Contact Us

Internal Vibrator

Internal Vibrator

External Vibrator

External Vibrator

Submersible Pump

Submersible Pump

Eccentric shaft

Eccentric shaft

Pendulum shaft

Pendulum shaft

Portable vbrator shaft

Portable vbrator shaft

Portable concrete mixer

Portable concrete mixer

Vertical concrete mixer

Vertical concrete mixer

Hydraulic concrete mixer

Hydraulic concrete mixer

Walk behind power trowel

Walk behind power trowel

Ride on power trowel

Ride on power trowel

Concrete screed

Concrete screed

Tamping rammer

Tamping rammer

Plate compactor

Plate compactor

Vibratory roller

Vibratory roller