Why Choose the Right Concrete Vibrator Shaft for Your Project?

Choosing the right Concrete Vibrator Shaft is crucial for any construction project. John Smith, a leading expert in concrete technology, emphasizes, "The right shaft ensures optimal compaction and longevity of the concrete."

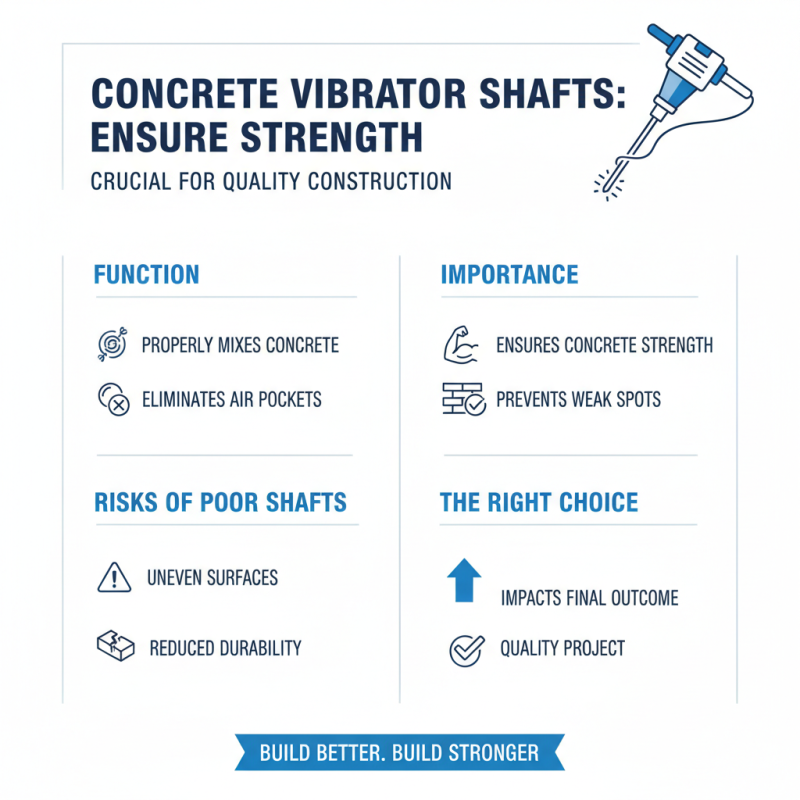

In the realm of construction, precision matters greatly. A Concrete Vibrator Shaft affects the quality of the finished product. It influences how well the concrete settles, impacting strength and durability. Using the wrong shaft can lead to inefficiencies. It might result in air pockets or weak spots in the structure.

Selecting the appropriate shaft can seem daunting. Many may overlook this detail, thinking any option will suffice. However, a mismatch can lead to costly mistakes. A skilled worker understands this, but not everyone might. Evaluating the specifications is necessary for achieving the desired results. This choice can define the project's success or failure.

Understanding the Importance of Concrete Vibrator Shafts in Construction

Concrete vibrator shafts play a crucial role in construction. They ensure that concrete is properly mixed, eliminating air pockets and ensuring strength. Without the right shaft, your project may face serious issues. A poorly functioning vibrator can lead to uneven surfaces and weak spots. Choosing the appropriate shaft can make a significant difference in the final outcome.

When selecting a concrete vibrator shaft, consider its length and diameter. A longer shaft can reach deeper places, while a thicker shaft may vibrate more effectively. Think about your project's specific needs. Each construction site has its unique challenges. The right shaft can address these issues and enhance efficiency.

Tips: Always check the compatibility of the shaft with your vibrator. A mismatch can lead to operational issues. Regularly inspect the shaft for wear and tear. A damaged shaft can compromise performance. Remember, a small detail can make or break your project. Don't overlook this aspect.

Different Types of Concrete Vibrator Shafts and Their Applications

Concrete vibrator shafts come in various types, each suited for specific applications. The two main categories are internal and external vibrators. Internal vibrators are often used in confined spaces for deep concrete pours. They ensure thorough compaction within the mix. External vibrators, on the other hand, sit on the surface. They are ideal for larger areas, such as pavements and slabs. In a study by the American Concrete Institute, it was shown that proper vibration can improve compressive strength by up to 20%.

Another common type is the handheld vibrator. These are portable and perfect for smaller jobs. They allow for precise control and are often used in residential projects. A report from the Portland Cement Association highlights that well-executed vibration can reduce air pockets and ensure a solid finish. However, improper use can lead to segregation. This leads to weaker concrete. Thus, understanding the application becomes crucial.

In choosing the right vibrator shaft, consider the project's scale. Project managers often overlook the power settings. Inadequate power can result in subpar outcomes. The choice of shaft is also influenced by the mix’s consistency. For example, high-slump mixes may require different vibration techniques compared to low-slump mixes. Balancing these factors is essential for achieving desired results.

Factors to Consider When Selecting a Concrete Vibrator Shaft

Selecting the right concrete vibrator shaft is crucial for project efficiency. The shaft’s length and diameter can significantly affect performance. A report by the American Concrete Institute (ACI) indicates that using the wrong shaft size can lead to poor compaction. This could cause costly rework in the long run. Contractors should assess the specific needs of their projects before making a choice.

Consider the vibration frequency of the shaft. According to industry standards, a frequency between 10,000 to 12,000 vibrations per minute optimizes concrete placement. Higher frequencies can lead to better consolidation, especially in high-slump mixes. Additionally, the material of the vibrator shaft matters. Steel is commonly chosen for its durability, but some projects may benefit from lightweight composite materials.

It's vital to match the vibrator shaft with the type of concrete used. Some mixes require special considerations for effective compaction. An error in this choice can lead to surface flaws or air pockets, diminishing structural integrity. Even experienced contractors sometimes overlook these details, resulting in significant project delays. Attention to these factors can make a difference between success and failure.

Common Mistakes to Avoid When Choosing a Concrete Vibrator Shaft

Choosing the right concrete vibrator shaft is crucial for project success. One common mistake is ignoring the specific needs of your project. Each job site has its own requirements. The shaft length, width, and type should align with the concrete's consistency and the size of the pour.

Another mistake arises from not considering the power source of the vibrator. Electric vibrators offer convenience, but if the site lacks good power access, you might face challenges. Gas-powered options are great for remote locations but come with their own limitations. Ensure the power source matches the vibrator’s design.

Tips: Always measure the depth and size of your pour. Take note of the surrounding environment. A shaft that’s too short or too long can lead to inconsistent results. Also, don’t overlook the material of the shaft. Stainless steel is sturdy, but it can be heavy. Consider a lighter option for easier handling. Reflect on past projects too. Analyze what worked and what didn’t. It can guide your choices now.

Best Practices for Maintaining Your Concrete Vibrator Shaft

Maintaining your concrete vibrator shaft is vital for efficiency. Proper care can enhance its lifespan. A worn or damaged shaft can lead to poor vibration, affecting the concrete. Regular inspections should be part of your routine. Look for signs of wear or corrosion. Sometimes, it’s easy to overlook these issues until it’s too late.

Cleaning is another crucial aspect. After each use, remove concrete splatter and debris. A clean shaft performs better and lasts longer. Use a wire brush or soft cloth, ensuring all residue is gone. Also, lubricate the shaft regularly. It helps to minimize friction and wear. However, avoid over-lubrication, as it can attract dirt.

You should also store the shaft properly. Ideally, keep it in a dry, clean area. Avoid placing heavy objects on it. This can cause bending or misalignment. Maintenance can seem tedious at times, but neglecting it leads to larger problems. Take time to reflect on your processes. Little efforts can lead to significant improvements in performance.

Concrete Vibrator Shaft Performance Comparison

Home

About Us

products

Resource

Blog

Contact Us

Internal Vibrator

Internal Vibrator

External Vibrator

External Vibrator

Submersible Pump

Submersible Pump

Eccentric shaft

Eccentric shaft

Pendulum shaft

Pendulum shaft

Portable vbrator shaft

Portable vbrator shaft

Portable concrete mixer

Portable concrete mixer

Vertical concrete mixer

Vertical concrete mixer

Hydraulic concrete mixer

Hydraulic concrete mixer

Walk behind power trowel

Walk behind power trowel

Ride on power trowel

Ride on power trowel

Concrete screed

Concrete screed

Tamping rammer

Tamping rammer

Plate compactor

Plate compactor

Vibratory roller

Vibratory roller