Why You Should Choose a Diesel Concrete Vibrator for Your Construction Needs

In the construction industry, efficiency and reliability are paramount, and equipment choice plays a critical role in achieving these goals. Among the various tools available, the Diesel Concrete Vibrator stands out as an exceptional choice for contractors looking to enhance their concrete placement tasks. This powerful machinery ensures optimal compaction, reducing air pockets and enhancing the overall strength of the concrete. Whether you're working on a small residential project or a large-scale commercial development, the Diesel Concrete Vibrator offers a unique blend of power and portability that makes it suitable for any construction site.

Moreover, the advantages of using a Diesel Concrete Vibrator extend beyond performance; they also include increased productivity and cost-effectiveness. With its robust engine and efficient vibration capabilities, this equipment minimizes project delays caused by curing time and compacting errors. By choosing a Diesel Concrete Vibrator, construction professionals can streamline their operations, ensuring that projects are completed on time and within budget. In this article, we will delve deeper into the compelling reasons to opt for a Diesel Concrete Vibrator for your construction needs, highlighting its benefits and impact on project outcomes.

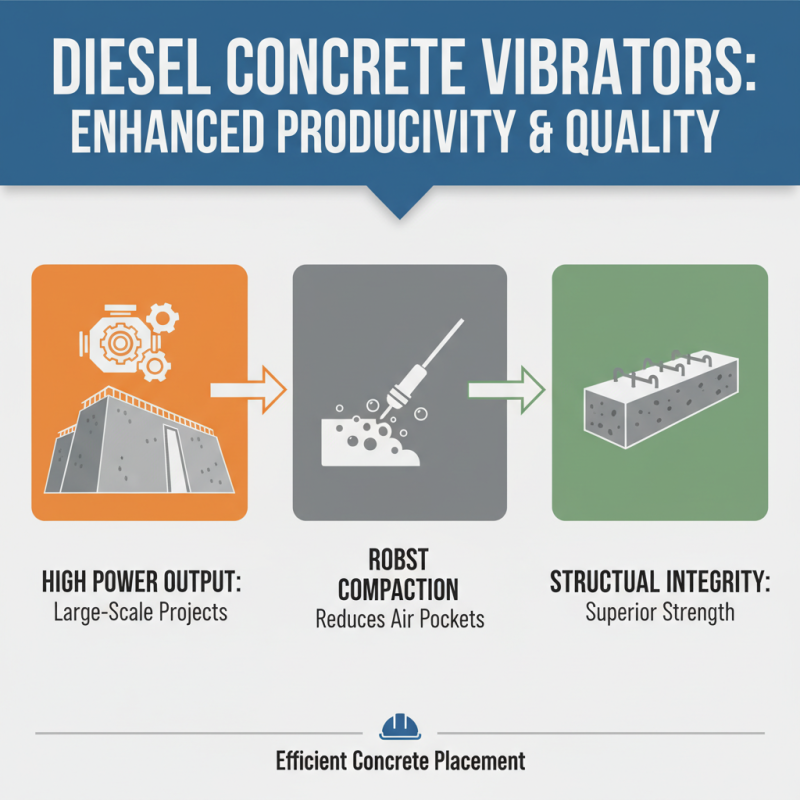

Benefits of Diesel Concrete Vibrators in Construction Projects

In the realm of construction, efficient concrete placement is crucial for achieving structural integrity. Diesel concrete vibrators stand out in this process, offering several advantages that enhance productivity and quality. One significant benefit of diesel-powered vibrators is their high power output, making them particularly effective for large-scale projects. With robust operation, these machines ensure thorough compaction of concrete, reducing air pockets and voids that can compromise the final product's strength.

Additionally, diesel concrete vibrators are renowned for their portability and independence from electric power sources. This feature is especially advantageous on remote job sites where access to electricity may be limited or nonexistent. The ability to operate using readily available diesel fuel allows construction teams to maintain efficiency in their work schedules, ensuring timely project completion. Furthermore, diesel vibrators often exhibit greater durability and resilience in harsh working conditions, making them a reliable choice for construction teams aiming for consistent performance under various environmental challenges.

How Diesel Vibrators Enhance Concrete Quality and Longevity

When it comes to achieving optimal concrete quality and extending the lifespan of structures, diesel concrete vibrators stand out as a superior choice. One of the primary benefits of using diesel vibrators is their ability to efficiently remove air voids and ensure proper compaction of the concrete mix. This process not only enhances the strength and durability of the concrete but also promotes an even distribution of aggregates, leading to a more homogenous finish. The powerful vibrations produced by diesel engines can penetrate deep into dense mixtures, securing a level of compaction that is harder to achieve with electric vibrators, particularly in large-scale projects or remote sites.

Moreover, the use of diesel concrete vibrators can significantly improve the longevity of concrete structures. With effective compaction, the risk of cracking and the formation of weak spots is minimized, ultimately resulting in a more resilient end product. The increased density and reduced porosity of the concrete also contribute to better resistance against weathering, chemical exposure, and other environmental factors that can deteriorate concrete over time. Thus, selecting a diesel vibrator is not just a choice for immediate construction needs but an investment in the long-term integrity and performance of the built environment.

Comparing Diesel Vibrators with Electric Alternatives: Pros and Cons

When considering the choice between diesel concrete vibrators and electric alternatives, several factors come into play, each with its own set of advantages and disadvantages. Diesel vibrators are typically favored for their robust performance and ability to operate in remote locations where electricity may not be readily available. They are often more powerful, which can lead to better consolidation of concrete, especially in large or demanding projects. Additionally, diesel engines usually offer longer run times, making them ideal for extensive construction tasks without frequent refueling breaks.

On the other hand, electric concrete vibrators present their own compelling benefits. They are generally easier to start and operate, with less noise and a lower carbon footprint. Maintenance can be simpler, as electric motors do not require the same level of upkeep as diesel engines. However, their reliance on electrical sources can limit mobility and may necessitate the use of generators for outdoor applications. This can alter the cost-effectiveness of the operation, particularly in large-scale projects where convenience and efficiency are paramount. Overall, the choice hinges on specific project requirements, budgetary considerations, and operational preferences.

Why You Should Choose a Diesel Concrete Vibrator for Your Construction Needs - Comparing Diesel Vibrators with Electric Alternatives: Pros and Cons

| Criteria |

Diesel Vibrators |

Electric Vibrators |

| Power Source |

Diesel Engine |

Electric Motor |

| Mobility |

Highly mobile for remote sites |

Limited to access to power sources |

| Power Output |

High power output for large jobs |

Variable, generally lower |

| Operating Cost |

Higher fuel costs |

Lower operating costs |

| Maintenance |

More complex, requires regular servicing |

Simpler maintenance routines |

| Noise Level |

Higher noise levels |

Generally quieter operation |

| Best Use Case |

Large construction sites, remote locations |

Small to medium projects, indoor use |

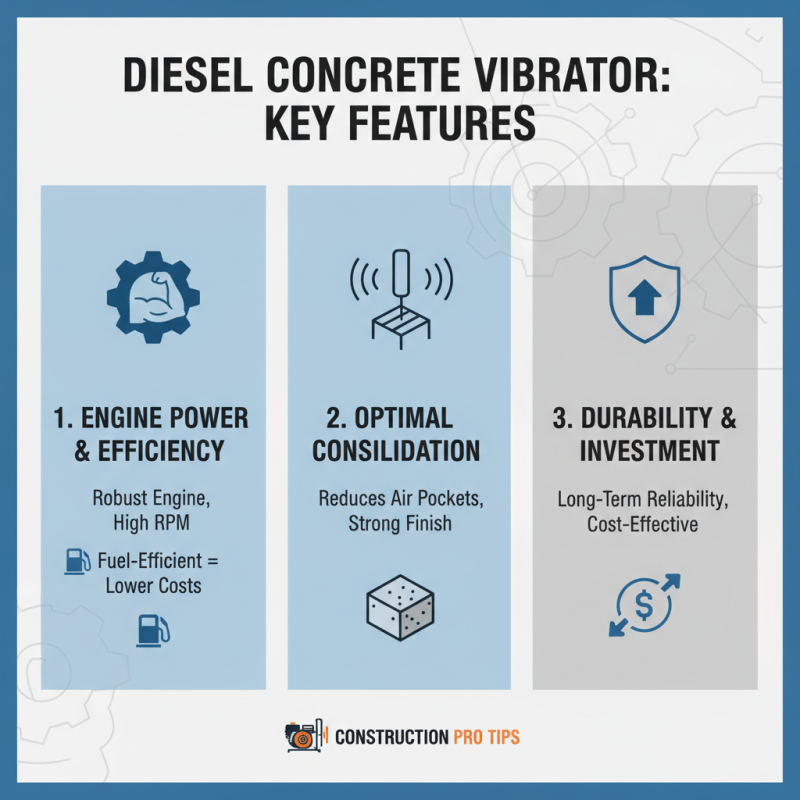

Key Features to Look for in a Diesel Concrete Vibrator

When selecting a diesel concrete vibrator for your construction needs, it is essential to focus on key features that enhance its performance and durability. First, consider the engine power and efficiency, as a robust engine ensures effective vibration for strong concrete compaction. Look for models with high RPM rates, as this will allow for optimal consolidation, reducing the risk of air pockets and ensuring a solid finished product. Additionally, a fuel-efficient engine can significantly reduce operational costs over time, making it a prudent investment for contractors.

Another critical aspect to consider is the design and build quality of the vibrator. A well-constructed unit will be both lightweight and sturdy, allowing for easy handling while maintaining durability on tough job sites. Pay attention to features like anti-vibration handles, which improve operator comfort and reduce fatigue during extended use. Furthermore, the availability of interchangeable heads can greatly enhance versatility, allowing the vibrator to adapt to various concrete types and project requirements effectively. With these features in mind, you can ensure that your diesel concrete vibrator meets the demands of modern construction.

Best Practices for Using Diesel Concrete Vibrators Effectively

When utilizing diesel concrete vibrators, it is crucial to adhere to best practices to maximize efficiency and achieve optimal results in your construction projects. First and foremost, operators should ensure that the equipment is maintained properly. Regular checks on the engine, fuel levels, and vibration mechanisms are essential to prevent breakdowns and maintain consistent performance. Additionally, operators should familiarize themselves with the specific requirements of the concrete mix being used, as different mixtures may require varying vibrational intensities and frequencies to achieve proper consolidation.

Another important practice is to carefully plan the timing and technique used during the vibration process. Applying vibrations too early can disrupt the setting process, while waiting too long can lead to inadequate consolidation. Operators should aim to use the vibrator in a systematic pattern, moving it slowly and methodically through the concrete to ensure even distribution of vibrations. Monitoring the work visually during the process will help in identifying if adjustments need to be made to achieve the desired consistency and eliminate air pockets within the concrete. By following these practices, users can significantly enhance the effectiveness of diesel concrete vibrators on site.

Why You Should Choose a Diesel Concrete Vibrator for Your Construction Needs

This bar chart illustrates essential specifications of diesel concrete vibrators, including vibration frequency, weight, fuel consumption, and engine power. Selecting a diesel concrete vibrator can enhance performance and efficiency in construction tasks.

Home

About Us

products

Resource

Blog

Contact Us

Internal Vibrator

Internal Vibrator

External Vibrator

External Vibrator

Submersible Pump

Submersible Pump

Eccentric shaft

Eccentric shaft

Pendulum shaft

Pendulum shaft

Portable vbrator shaft

Portable vbrator shaft

Portable concrete mixer

Portable concrete mixer

Vertical concrete mixer

Vertical concrete mixer

Hydraulic concrete mixer

Hydraulic concrete mixer

Walk behind power trowel

Walk behind power trowel

Ride on power trowel

Ride on power trowel

Concrete screed

Concrete screed

Tamping rammer

Tamping rammer

Plate compactor

Plate compactor

Vibratory roller

Vibratory roller