How to Choose the Best Compactor Equipment for Your Needs?

Choosing the right compactor equipment is crucial for efficient waste management. Businesses often face the dilemma of which type suits their needs best. Various models and specifications exist, making the selection process overwhelming.

Before selecting compactor equipment, assess your requirements thoroughly. Consider the volume of waste you generate and the type of materials you handle. For instance, a construction site may need different equipment than a retail store. Think about your operation's size and budget. These factors should influence your decision.

Reflect on the importance of reliability and maintenance needs. Some machines might appear attractive at first but require frequent repairs. Investing in durable compactor equipment can save money in the long run. However, understand that every option has its pros and cons. An informed choice can lead to better efficiency and less frustration.

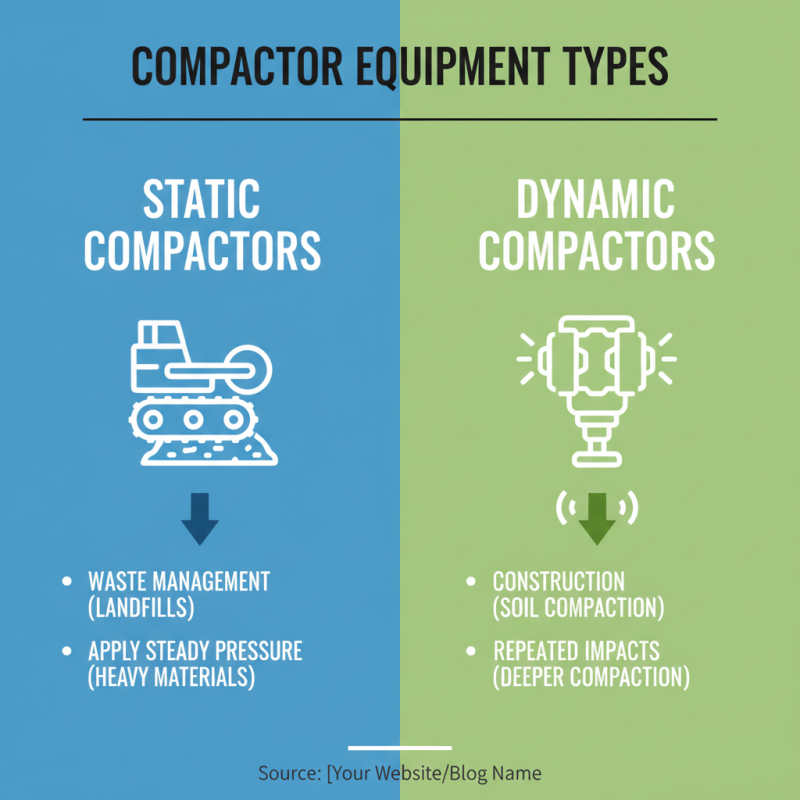

Understanding Different Types of Compactor Equipment Available

When selecting compactor equipment, understanding the different types is crucial. There are mainly two categories: static and dynamic compactors. Static compactors are best for waste management in landfills. They apply steady pressure to compress heavy materials. Meanwhile, dynamic compactors are better suited for construction. They utilize repeated impacts to achieve deeper soil compaction.

According to industry reports, the global compaction equipment market was valued at over $4 billion in 2020. It is projected to grow at a rate of 5% annually. This growth highlights the increasing demand for efficient waste management and soil compaction solutions. Each type serves specific needs, emphasizing the importance of assessing your unique requirements carefully.

Commonly, users may overlook the maintenance costs. Neglecting upkeep can lead to expensive repairs down the line. Evaluating the total cost of ownership is vital. Misjudgments can occur when prioritizing initial purchase prices over long-term efficiency. Choosing equipment based on immediate needs might result in mismatches for future projects. This reflection is essential in making informed decisions.

Assessing Your Specific Compaction Needs and Requirements

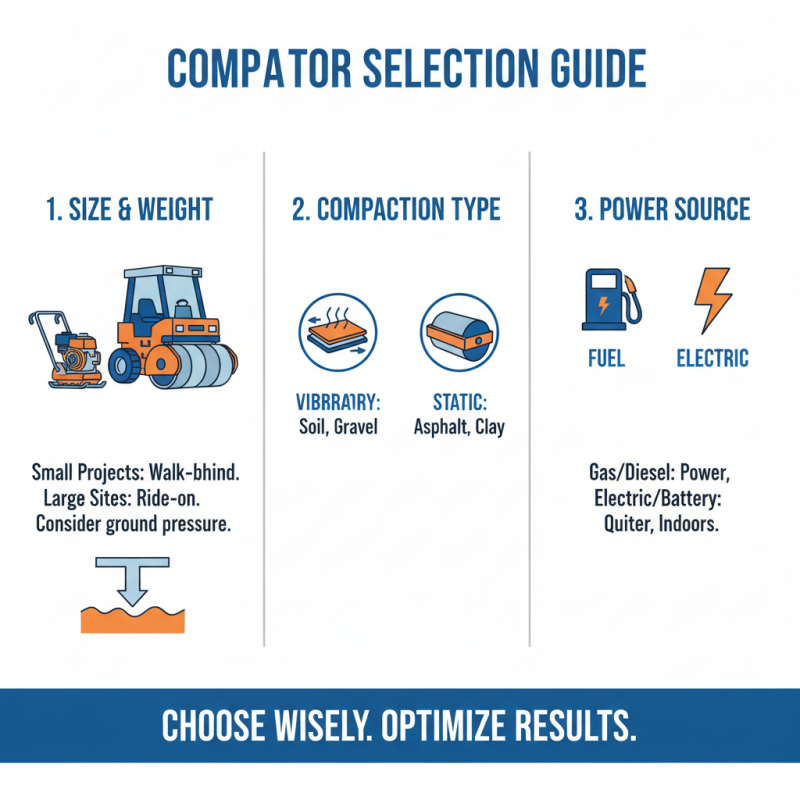

When choosing compactor equipment, assessing your specific compaction needs is essential. Understanding the material you will be compacting is a first step. Different materials require different compaction force and methods. For instance, loose soil extends the need for vibratory plate compactors, while asphalt often requires a roller compactor. According to a report from the International Society of Automation, choosing the right equipment can increase efficiency by up to 30%.

Evaluate the project scale and job site conditions. Are you compacting for a small residential area or a large commercial project? Compacting larger areas often needs heavy machinery, while smaller sites might benefit from portable units. Proper assessment of these factors can significantly reduce time and costs.

Tips: Always test the compaction in a small area before full deployment. Also, consider the noise and vibration levels. Excessive noise can hinder productivity. Factory noise data can indicate potential impacts on surrounding environments. Effectively balancing equipment choice with operational needs is crucial. Avoid underestimating the importance of ongoing training for operators to ensure proper equipment use.

Evaluating Key Features and Specifications of Compactors

When choosing a compactor, key features are essential. Understand the size and weight of the machine. Compactors come in various sizes, suitable for small projects or large sites. Assess the weight impact on the surface being compacted. Too much weight can cause damage.

Also, consider the power source. Compactors may be gas, electric, or diesel-powered. Each type has its pros and cons. Electric models are quieter and better for indoor use. However, gas machines typically deliver more power. Check your job requirements before deciding.

Look at the compaction force, too. This determines how effectively the machine compresses materials. Higher compaction forces can handle tough jobs. But, they may also lead to overspending on features you may not need. Think critically about the tasks at hand. Each project varies in demands. Adapting the compactor to match these demands is crucial for efficiency and results.

Considering Budget and Cost-Effectiveness in Selection

When selecting compactor equipment, budget and cost-effectiveness are critical. According to a recent industry report, businesses often overlook total cost of ownership. This includes maintenance, fuel efficiency, and operational costs. A lower initial price may lead to higher expenses later.

Detailed analysis reveals that equipment with higher durability often saves money over time. For instance, heavy-duty models typically require fewer repairs. However, this initial investment can seem daunting. Companies must balance upfront costs against long-term benefits.

Evaluating your specific needs is vital. Is the compactor needed for regular or occasional use? A report from a construction equipment analysis found that 40% of users make purchases without considering usage frequency. This leads to wasted resources and unnecessary expenses. Investing in the right compactor aligns performance with budgetary constraints. Making informed decisions can prevent costly mistakes and improve overall efficiency.

Comparison of Compactor Equipment Costs and Features

Researching Brands and Customer Reviews for Reliable Equipment

When researching compactor equipment, brand reputation matters. Reliable brands often have consistent customer reviews. A study by *Industry Insights* found that 72% of buyers trust online reviews as much as personal recommendations. This statistic is essential when evaluating various models. Poor reviews can highlight potential issues. Check for feedback on performance, durability, and customer service.

Look closely at user experiences. Sometimes, reviews indicate a lack of proper support after purchase. Buyers may express frustration over complex features that are hard to operate. A report from *Construction Equipment Research* revealed that 35% of compactor users regret their purchase due to misunderstood specifications. It's vital to ensure the equipment fits your specific needs.

Weight and size significantly influence compactor effectiveness. Some heavy machines might be too cumbersome for small projects. According to *Market Research Future*, lighter models cause less ground disturbance and are easier to maneuver. However, they may not compress as effectively. Finding the balance between weight and power is critical in your decision-making process.

How to Choose the Best Compactor Equipment for Your Needs?

| Equipment Type |

Weight Capacity (tons) |

Engine Type |

Fuel Efficiency (mpg) |

User Rating (out of 5) |

Common Applications |

| Vibratory Roller |

10 |

Diesel |

15 |

4.5 |

Road construction, Landfill |

| Static Compactor |

8 |

Electric |

20 |

4.0 |

Waste management, Recycling |

| Pneumatic Roller |

12 |

Gas |

25 |

4.3 |

Asphalt paving, Gravel |

| Plate Compactor |

5 |

Gas |

30 |

4.7 |

Soil compaction, Concrete |

| Sheepsfoot Roller |

15 |

Diesel |

18 |

4.6 |

Subgrade preparation, Heavy soil |

Home

About Us

products

Resource

Blog

Contact Us

Internal Vibrator

Internal Vibrator

External Vibrator

External Vibrator

Submersible Pump

Submersible Pump

Eccentric shaft

Eccentric shaft

Pendulum shaft

Pendulum shaft

Portable vbrator shaft

Portable vbrator shaft

Portable concrete mixer

Portable concrete mixer

Vertical concrete mixer

Vertical concrete mixer

Hydraulic concrete mixer

Hydraulic concrete mixer

Walk behind power trowel

Walk behind power trowel

Ride on power trowel

Ride on power trowel

Concrete screed

Concrete screed

Tamping rammer

Tamping rammer

Plate compactor

Plate compactor

Vibratory roller

Vibratory roller