Top Benefits of Using a Reversible Compactor in 2025 for Efficient Construction

In the ever-evolving landscape of construction, the demand for efficient and sustainable machinery has never been higher. As we enter 2025, the Reversible Compactor has emerged as a pivotal tool for contractors aiming to enhance productivity and achieve optimal compaction results. According to a recent report by the International Construction Equipment Association, over 75% of construction professionals reported an increase in project efficiency when utilizing advanced compaction equipment, including reversible compactors. This highlights a notable trend where innovative machinery plays a critical role in reducing project timelines and costs.

Industry expert Dr. Emily Carter, a leading voice in construction technology, emphasizes the versatility of the Reversible Compactor, stating, "The adaptability of reversible compactors allows for comprehensive compaction in tight spaces, which is increasingly essential as urban construction sites become more congested." This sentiment reflects the industry's shift towards equipment that not only meets technical specifications but also responds to the unique challenges posed by modern construction projects. With features designed for maneuverability and effective compressive strength, the Reversible Compactor stands out as an indispensable asset for contractors looking to optimize their workflows in 2025 and beyond.

Understanding Reversible Compactors: Features and Functionality

Reversible compactors are becoming an essential tool in the construction industry due to their unique features and operational efficiency. These machines are designed to deliver enhanced compaction performance on various soil types, making them ideal for road construction, trench work, and foundation laying. According to a 2023 report from the Construction Equipment Association, the demand for reversible compactors is projected to grow by 15% in the coming year, driven by the increasing need for efficient soil compaction in tight spaces.

The functionality of reversible compactors lies in their dual-direction capabilities. Operators can navigate easily around obstacles, significantly reducing the time and effort required for compaction tasks. This feature is particularly beneficial when working on congested job sites where maneuverability is crucial. Moreover, many reversible compactors come equipped with advanced features such as vibration control systems and adjustable operational speeds, allowing for precision compaction without damaging underlying materials.

Tips: When selecting a reversible compactor, consider the weight and size of the unit in relation to your project needs. Heavier models typically provide better compaction for asphalt and deeper layers of soil, while lighter models are more suitable for granular materials. Always ensure that the machine is well-maintained, checking the hydraulic systems and tracks regularly to minimize downtime and enhance productivity on site.

Top Benefits of Using a Reversible Compactor in 2025 for Efficient Construction

| Feature |

Benefit |

Use Case |

Expected Impact |

| Dual Directional Operation |

Improves efficiency and reduces time on site |

Compacting in tight spaces and around obstacles |

Up to 30% reduction in project timeline |

| Enhanced Maneuverability |

Easier to navigate in constrained areas |

Urban construction sites with limited space |

Increased worker efficiency and safety |

| Vibration Control |

Reduces stress on operators and equipment |

Long-term use in foundation work |

Enhanced operator comfort and less wear on machines |

| Compact Design |

Easy transport and storage |

Multi-site operations |

Cost savings on transport logistics |

| Adjustable Compaction Force |

Tailors performance to different types of soil |

Projects with variable ground conditions |

Improved compaction quality and project outcomes |

Advantages of Reversible Compactors in Modern Construction Methods

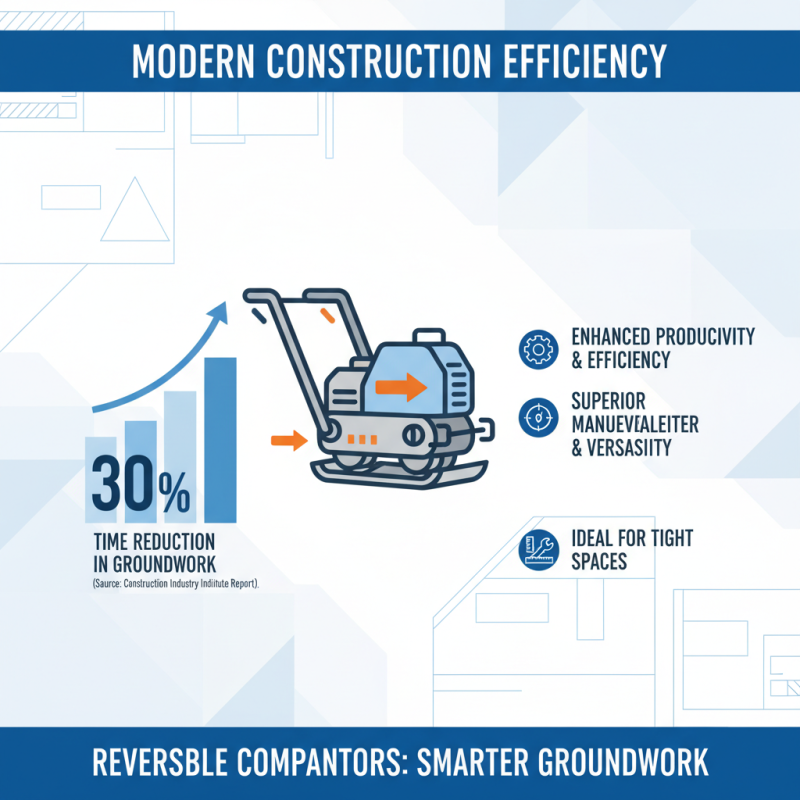

In modern construction methods, the adoption of reversible compactors has become essential for enhancing efficiency and productivity on job sites. According to a report by the Construction Industry Institute, the use of advanced compaction equipment can lead to up to a 30% reduction in time spent on groundwork preparation. Reversible compactors, known for their ability to perform in both forward and reverse directions, provide superior maneuverability and versatility, making them ideal for tight spaces and complex site conditions.

Another significant advantage of reversible compactors is their effectiveness in achieving optimal soil density, which is crucial for ensuring the stability of various structures. The American Society of Civil Engineers emphasizes that proper compaction can reduce the risk of future settlement and structural failure, ultimately saving costs associated with repairs and maintenance. Furthermore, recent advancements in engine technology have resulted in more eco-friendly models that offer lower emissions and fuel consumption, aligning with the industry’s increasing focus on sustainability. As construction practices evolve, integrating reversible compactors into projects not only meets current environmental standards but also enhances overall project efficiency and site safety.

Environmental Benefits of Using Reversible Compactors in 2025

In 2025, environmental consciousness in the construction industry is at an all-time high, and the use of reversible compactors demonstrates a commitment to sustainable practices. These machines are designed to efficiently compact soil, asphalt, and other materials, which reduces the need for additional resources and minimizes waste. By effectively achieving desired compaction with fewer passes, reversible compactors help to conserve energy and decrease CO2 emissions, making them an environmentally friendly option on job sites.

Moreover, reversible compactors use innovative technologies that improve fuel efficiency, contributing to a significant reduction in greenhouse gas emissions. Their compact design allows for better maneuverability in tight spaces, which translates to less disturbance of the surrounding environment. By reducing noise levels and minimizing soil disruption, reversible compactors support eco-conscious construction practices that prioritize the preservation of local ecosystems. As the industry moves towards greener solutions, adopting reversible compactors aligns operational efficiency with environmental responsibility, paving the way for more sustainable construction methods in the years to come.

Cost-Effectiveness of Reversible Compactors for Construction Projects

The construction industry is constantly striving for greater efficiency and cost-effectiveness, and in 2025, reversible compactors are poised to play a pivotal role in achieving these goals. According to a report from the Construction Industry Research Board, projects utilizing reversible compactors can save up to 30% in labor costs due to their enhanced maneuverability and ease of operation. This not only reduces the time spent on site but also minimizes the potential for costly delays, making it a wise investment for contractors aiming to optimize budgets.

In addition to labor savings, reversible compactors are designed to maximize material compaction. Studies have shown that projects employing these machines can achieve a compaction rate nearly 20% higher than those using traditional models, resulting in fewer layers needed for successful applications. This efficiency translates directly to reduced material costs and less waste—key factors that many construction companies are increasingly focusing on as sustainability becomes more critical.

Tips: When considering the integration of reversible compactors into your projects, assess the specific job site conditions and compaction requirements. Proper training for operators can also enhance the performance and longevity of the equipment. Lastly, ensure regular maintenance checks to keep the machinery in optimal working condition, reducing potential downtime and extending the lifespan of your investment.

Top Benefits of Using a Reversible Compactor in 2025 for Efficient Construction

The bar chart above illustrates the top benefits of using a reversible compactor in construction projects in 2025. These benefits include cost savings, efficiency, versatility, safety, and environmental impact, rated on a scale of 1 to 10. Using a reversible compactor significantly enhances operations on construction sites, making it a valuable investment for contractors.

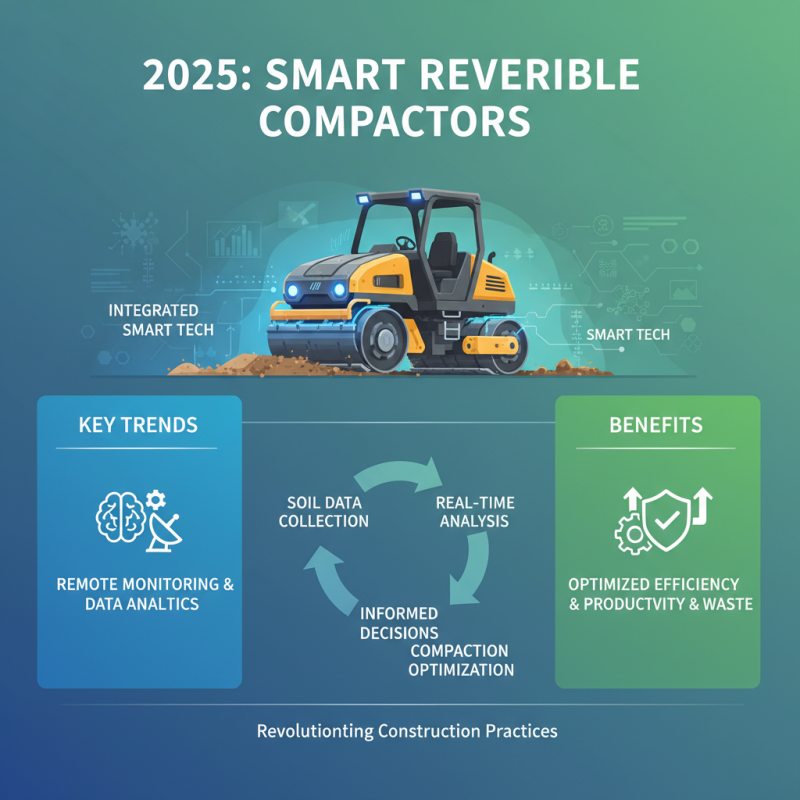

Future Trends in Reversible Compactor Technology for Efficient Use

As we move into 2025, the evolution of reversible compactor technology is set to revolutionize construction practices significantly. One of the most notable trends is the integration of smart technology into these machines, enabling advanced data analytics and remote monitoring. This allows operators to optimize compaction processes in real-time, improving efficiency and reducing the likelihood of errors. With the ability to collect and analyze data on soil conditions and compaction patterns, construction teams can make informed decisions that enhance productivity and minimize resource wastage.

Another key trend is the focus on sustainability and energy efficiency in reversible compactors. Manufacturers are increasingly adopting eco-friendly designs that utilize cleaner fuels and advanced hydraulic systems to reduce emissions and energy consumption. Innovations such as electric-powered compactors are also gaining traction, providing a quieter and more environmentally friendly option for urban construction sites. These developments not only comply with stricter environmental regulations but also cater to the growing demand for sustainable construction methods. By investing in these advanced reversible compactors, construction companies can enhance their operational efficiency while contributing to a greener future.

Home

About Us

products

Resource

Blog

Contact Us

Internal Vibrator

Internal Vibrator

External Vibrator

External Vibrator

Submersible Pump

Submersible Pump

Eccentric shaft

Eccentric shaft

Pendulum shaft

Pendulum shaft

Portable vbrator shaft

Portable vbrator shaft

Portable concrete mixer

Portable concrete mixer

Vertical concrete mixer

Vertical concrete mixer

Hydraulic concrete mixer

Hydraulic concrete mixer

Walk behind power trowel

Walk behind power trowel

Ride on power trowel

Ride on power trowel

Concrete screed

Concrete screed

Tamping rammer

Tamping rammer

Plate compactor

Plate compactor

Vibratory roller

Vibratory roller