Top 10 Benefits of Using Concrete Vibrating Machines in Construction

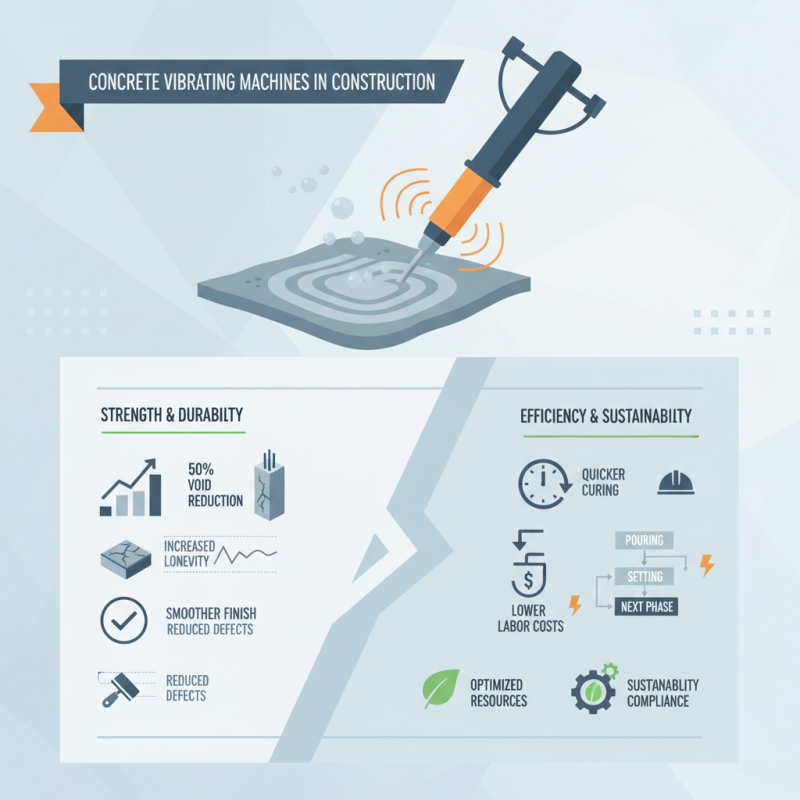

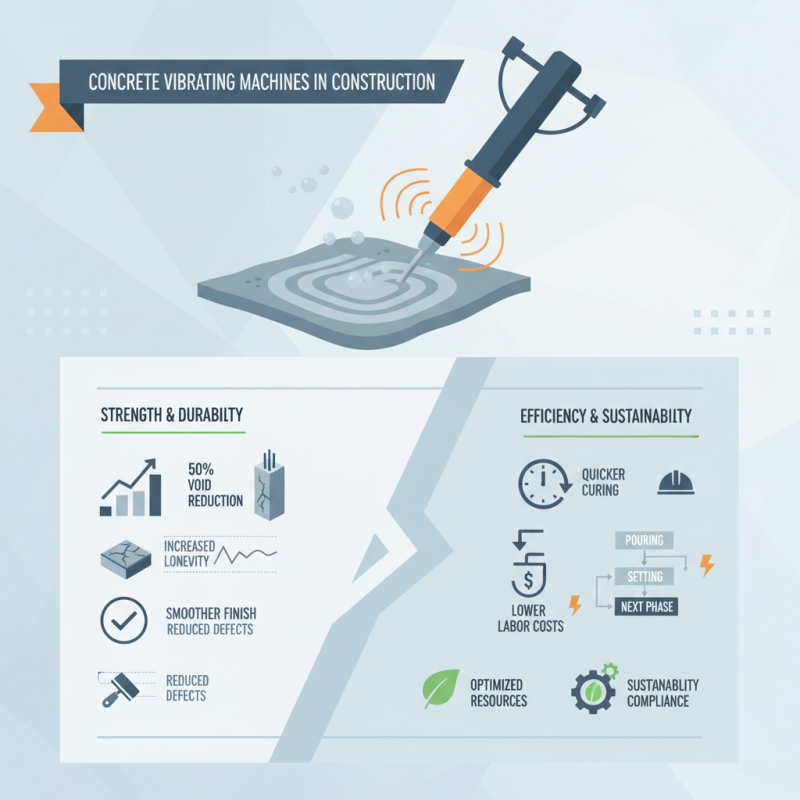

In the construction industry, the use of high-quality materials and advanced technologies is paramount to ensure the integrity and durability of structures. Among these technologies, the Concrete Vibrating Machine plays a pivotal role in enhancing the overall effectiveness of concrete mixing and pouring processes. According to the American Concrete Institute, proper vibration of concrete can lead to a reduction in voids by up to 50%, thereby increasing the strength and longevity of the finished product. Moreover, data from the National Ready Mixed Concrete Association highlights that projects employing vibration tools receive higher workability scores, resulting in a smoother finish and reduced likelihood of defects.

The benefits of utilizing Concrete Vibrating Machines extend beyond mere aesthetics; they significantly impact the efficiency of construction operations. Research indicates that vibration techniques can accelerate the curing process, enabling quicker project turnaround and potentially lower labor costs. A report from the International Journal of Engineering Research and Applications identifies that well-vibrated concrete sets faster, reducing the time construction teams need to wait before moving on to subsequent phases. As the industry continues to evolve, integrating advanced machinery like Concrete Vibrating Machines not only optimizes resource utilization but also ensures compliance with growing sustainability standards in construction practices.

Benefits of Enhanced Concrete Compaction for Structural Integrity

Enhanced concrete compaction is crucial for ensuring structural integrity in construction projects. Concrete vibrating machines significantly improve the density and strength of concrete by effectively eliminating air bubbles and voids that can weaken the final product. According to a report from the American Concrete Institute (ACI), properly compacted concrete can increase compressive strength by up to 25%, leading to more durable and resilient structures. This is particularly vital in high-stakes constructions like bridges and skyscrapers, where safety and longevity are paramount.

Moreover, enhanced concrete compaction facilitated by vibrating machines minimizes the risk of cracking and shrinkage, which can compromise a structure’s overall integrity. The National Ready Mixed Concrete Association (NRMCA) notes that a well-compacted concrete mix reduces the likelihood of maintenance issues over time, thereby lowering long-term project costs. Regular use of concrete vibrating machines can ensure uniform consistency, fostering greater structural stability and performance in varying environmental conditions.

Tips for achieving optimal results with concrete vibrating machines include ensuring the correct frequency and amplitude settings for the specific mix being used, which can vary based on aggregate size and type. Additionally, it is essential to monitor the duration of vibration to avoid over-vibration, which can lead to segregation and compromised quality. For best practices, always conduct pre-construction trials to determine the most effective vibratory approach for your project.

Top 10 Benefits of Using Concrete Vibrating Machines in Construction

| Benefit |

Description |

Impact on Structural Integrity |

| Improved Compaction |

Enhances the density of concrete, reducing voids. |

Increases strength and durability. |

| Reduced Air Pockets |

Minimizes trapped air that can weaken concrete. |

Improves load-bearing capacity. |

| Uniform Mixture |

Ensures consistent distribution of materials. |

Enhances structural performance. |

| Faster Setting Time |

Allows quicker construction timelines. |

Reduces project delays. |

| Reduced Cracking |

Decreases the likelihood of cracks during curing. |

Maintains structural integrity over time. |

| Enhanced Surface Finish |

Results in smoother surfaces without blemishes. |

Improves aesthetic appeal and longevity. |

| Energy Efficiency |

Reduces energy consumption during placement. |

Lowers operational costs. |

| Labor Efficiency |

Less manual effort required for compaction. |

Increases productivity on site. |

| Longer Lifespan |

Structures are more resistant to degradation. |

Extends usability of concrete constructions. |

| Cost-Effective |

Reduces the need for repairs and replacements. |

Saves money in the long run. |

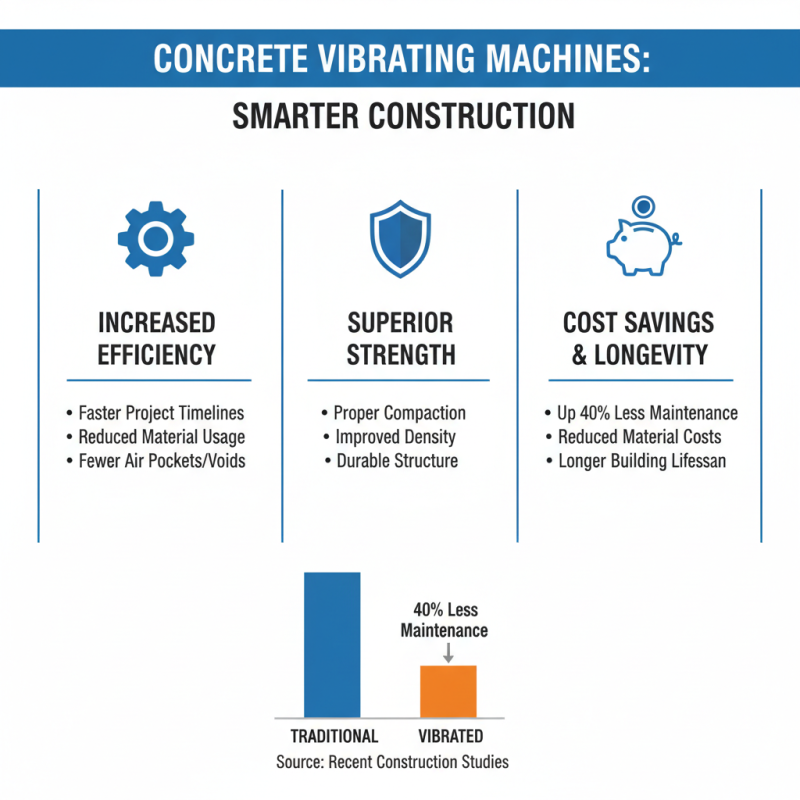

Increased Efficiency in Construction Processes with Vibrating Machines

Using concrete vibrating machines in construction significantly enhances efficiency in various processes. Recent studies indicate that properly compacted concrete results in a stronger and more durable structure, which can lead to a reduction in maintenance costs by up to 40% over the lifecycle of a building. The increased efficiency brought about by vibrating machines minimizes the risk of air pockets and voids in the concrete, providing better density and strength. In practical terms, this means fewer materials are needed to achieve the same structural integrity, ultimately translating into cost savings and faster project timelines.

Moreover, industry reports suggest that construction projects employing concrete vibrators can see a reduction in labor time by nearly 25%. This time-saving attribute allows project managers to allocate labor resources more effectively, speeding up the overall construction timeline. With vibrating machines, concrete can be poured and set more quickly, resulting in shorter curing times and a quicker path to completion. As the construction industry continues to embrace technological advancements, the use of vibrating machines stands out as a key factor in streamlining operations and maximizing productivity, enabling teams to deliver high-quality results within tighter deadlines.

Reduction of Air Voids Leading to Improved Material Durability

The utilization of concrete vibrating machines in construction has profound benefits, particularly in the reduction of air voids within the concrete mix. Air voids can significantly compromise the integrity and durability of concrete structures. According to industry reports, approximately 5-10% of air voids in concrete can lead to a noticeable decrease in compressive strength and overall lifespan of the material. Ensuring proper vibration during the pouring process can minimize these voids, resulting in denser, more durable concrete that withstands environmental stressors effectively.

Moreover, effective vibration improves the bonding between aggregates and the cement paste, enhancing the material's cohesiveness. This process not only boosts strength but also aids in resisting water infiltration and freeze-thaw cycles, which are critical factors in areas subjected to harsh weather conditions. Studies indicate that structures with reduced air voids can experience up to a 30% improvement in durability over time, making the initial investment in vibrating machinery a cost-effective choice for long-term performance.

Tips: When operating concrete vibrating machines, aim for uniform vibration throughout the mix. Avoid excessive vibration, as it can lead to segregation of materials. Regularly inspect and maintain your equipment to ensure optimal performance, and always consider testing concrete samples for air void content to gauge effectiveness.

Minimization of Costly Repairs Through Quality Control in Pouring

The use of concrete vibrating machines in construction significantly enhances the quality of poured concrete, leading to fewer costly repairs. When concrete is poured, it can often contain air bubbles or voids, which compromise its overall integrity. By utilizing vibrating machines, these imperfections are minimized as the vibrations help to settle the concrete and remove trapped air. This process ensures a denser, more uniform mixture, which ultimately translates to increased strength and durability in the finished structure.

To maximize the benefits of concrete vibrating machines, here are a few tips to consider: First, ensure that the vibrating machine is calibrated correctly for the specific type of concrete being used. Different mixtures may require different vibration intensities. Secondly, timing is critical; begin vibrating immediately after the concrete is poured and continue until the mixture has settled adequately. Lastly, avoid over-vibrating, which can lead to segregation of the aggregate and adversely affect the concrete’s strength. By adhering to these guidelines, contractors can significantly reduce the likelihood of defects, ensuring that costly repairs are kept at bay.

Investing in quality control processes during pouring not only saves on repairs but also enhances workflow efficiency. As structures become more reliable, the long-term costs decrease, paving the way for smoother project timelines and greater client satisfaction. By prioritizing proper techniques and using the right equipment, construction teams can deliver superior results that withstand the test of time.

Top 10 Benefits of Using Concrete Vibrating Machines in Construction

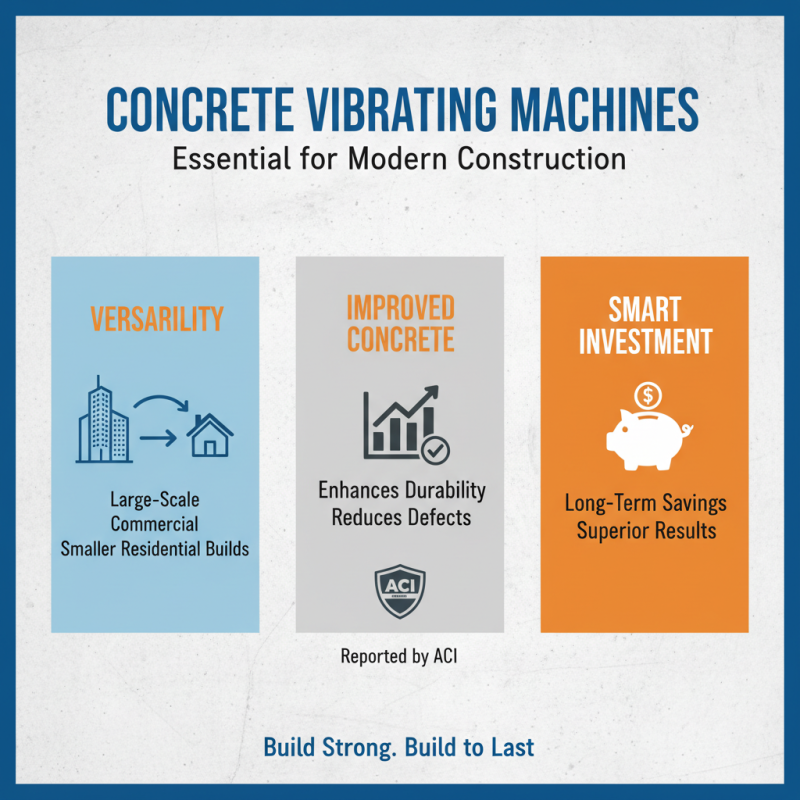

Versatility of Concrete Vibrating Machines Across Various Projects

Concrete vibrating machines have become an essential tool in modern construction, offering unparalleled versatility across a variety of projects. These machines are not only used in large-scale commercial constructions but also play a vital role in smaller residential builds. According to a report by the American Concrete Institute, properly consolidated concrete significantly enhances durability and reduces the likelihood of defects, making vibrating machines a worthy investment for any construction endeavor.

The adaptability of concrete vibrating machines means they can be employed in diverse applications, including road construction, bridge buildings, and even decorative concrete pourings. In fact, the International Journal of Advanced Research in Engineering and Technology highlights that projects utilizing advanced vibration techniques can reduce air voids in concrete by up to 80%, leading to a stronger final product. This versatility ensures that whether a project is focused on structural integrity or aesthetic appeal, concrete vibrating machines can meet these demands.

**Tips: For optimal performance of concrete vibrating machines, always ensure the right frequency and amplitude settings according to the specific project needs. This not only improves efficiency but also enhances the quality of the concrete finish. Additionally, consider the scale of your project; larger distributions of aggregate often require more robust vibration techniques to achieve effective consolidation.**

Home

About Us

products

Resource

Blog

Contact Us

Internal Vibrator

Internal Vibrator

External Vibrator

External Vibrator

Submersible Pump

Submersible Pump

Eccentric shaft

Eccentric shaft

Pendulum shaft

Pendulum shaft

Portable vbrator shaft

Portable vbrator shaft

Portable concrete mixer

Portable concrete mixer

Vertical concrete mixer

Vertical concrete mixer

Hydraulic concrete mixer

Hydraulic concrete mixer

Walk behind power trowel

Walk behind power trowel

Ride on power trowel

Ride on power trowel

Concrete screed

Concrete screed

Tamping rammer

Tamping rammer

Plate compactor

Plate compactor

Vibratory roller

Vibratory roller