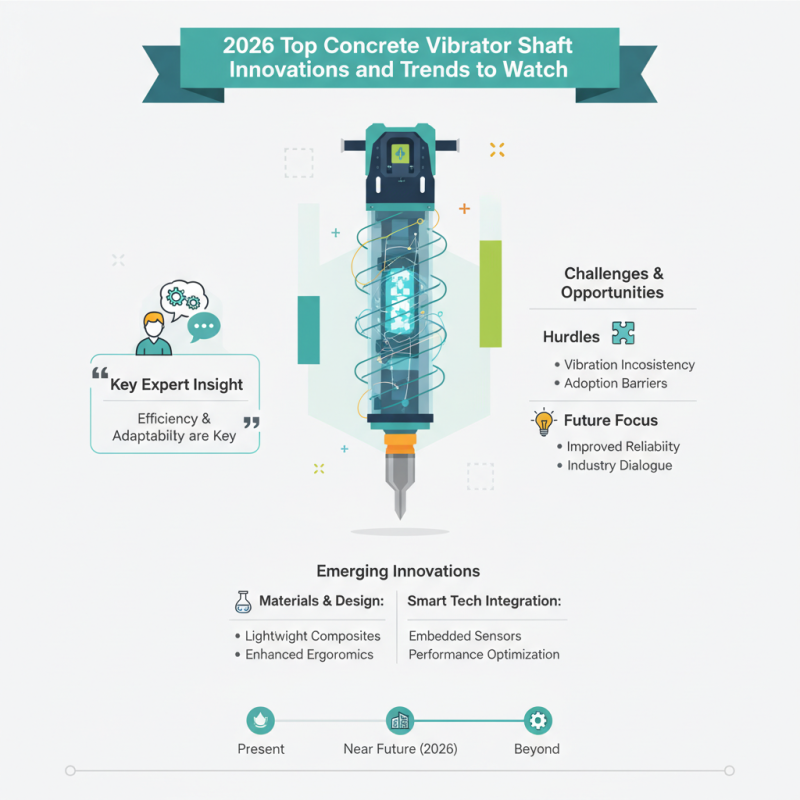

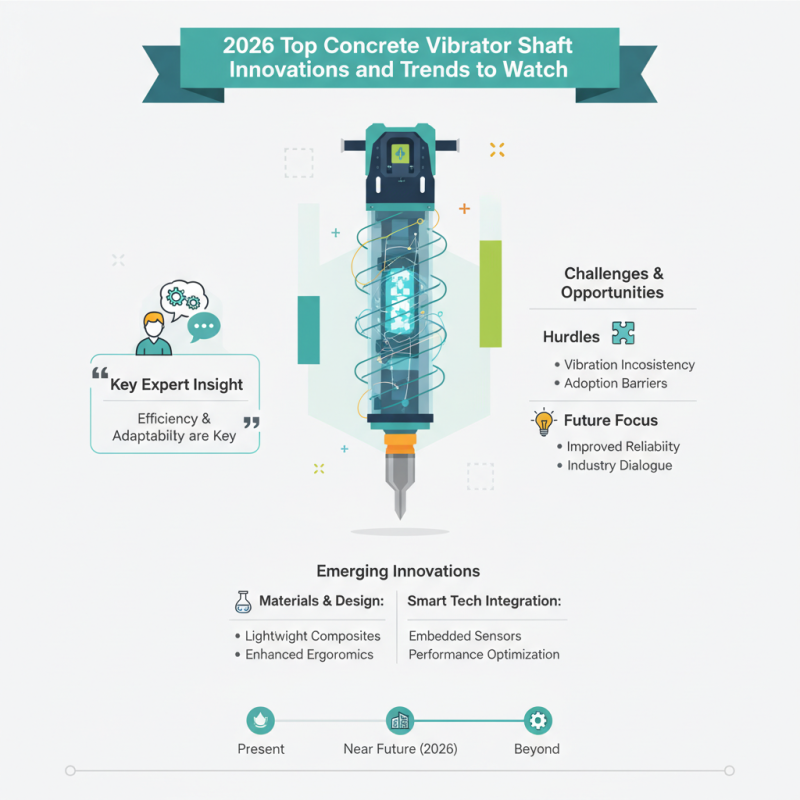

2026 Top Concrete Vibrator Shaft Innovations and Trends to Watch?

In the ever-evolving world of construction, the "Concrete Vibrator Shaft" remains a key component. As we approach 2026, industry experts are closely observing new innovations and trends. John Smith, a leading authority in concrete technology, remarked, "The future of concrete vibrators is about efficiency and adaptability." His insights highlight an urgent need for advancements in this sector.

New materials and designs are emerging, promising to enhance the functionality of Concrete Vibrator Shafts. Lightweight composites may soon replace traditional metals, improving ease of use. Yet, there's room for improvement. Many existing models still struggle with vibration consistency. Users deserve better reliability.

The landscape is shifting. Companies are investing in smarter technologies, integrating sensors to optimize performance. However, challenges remain in widespread adoption. The industry must address these hurdles. The future depends on blending innovation with practical usability in Concrete Vibrator Shafts. An ongoing dialogue will pave the way forward.

Emerging Technologies in Concrete Vibrator Shaft Design for 2026

In 2026, concrete vibrator shaft design is set to evolve significantly. New technologies are emerging that enhance efficiency and performance. For instance, advanced composite materials are being utilized, providing increased durability while reducing weight. Industry data suggests that these innovations can lead to a 15% boost in productivity at job sites.

Sensor integration is another trend to watch. Smart vibration sensors allow real-time monitoring of concrete consistency. This technology helps prevent over-vibration, which can weaken structures. A survey indicated that about 30% of concrete applications face issues due to poor vibration techniques. By adopting smart sensors, companies can ensure better outcomes.

Tip: Regular maintenance of equipment is crucial. It can extend the lifespan of equipment by up to 25%.

Emerging automation in manufacturing processes is also noteworthy. Automated production lines for concrete vibrators can minimize human error and increase precision. However, this shift must be handled carefully. Transitioning to new methods may disrupt existing workflows. Companies should consider gradual adoption to manage these changes effectively.

Tip: Invest in training for staff to adapt to new technologies seamlessly.

2026 Top Concrete Vibrator Shaft Innovations and Trends

Key Materials Advancements Driving Concrete Vibrator Shaft Performance

In recent years, advancements in materials have significantly enhanced the performance of concrete vibrator shafts. According to a report by Allied Market Research, the global construction equipment market is projected to reach $210 billion by 2025, indicating a robust growth influenced by innovative materials. Lightweight alloys and composites are now commonly used in manufacturing these shafts. They reduce weight while maintaining structural integrity, which makes them more efficient.

The trend toward incorporating high-strength polymers is also on the rise. They are less prone to corrosion and can withstand extreme conditions. For instance, studies show that polymer-based shafts exhibit up to a 30% increase in durability compared to traditional materials. However, it's important to note that not all polymers perform equally well in every environment. Their performance can be inconsistent when exposed to certain chemical compounds commonly found in concrete mixtures.

Moreover, the integration of smart technology into vibrator shafts is beginning to surface. This includes sensors that monitor vibration patterns in real-time. While early adopters report improved efficiency, the long-term reliability of these technologies remains untested. The industry must reflect on these innovations critically, as the benefits may come with unforeseen challenges. Balancing innovation with practicality is crucial for future developments in concrete vibrators.

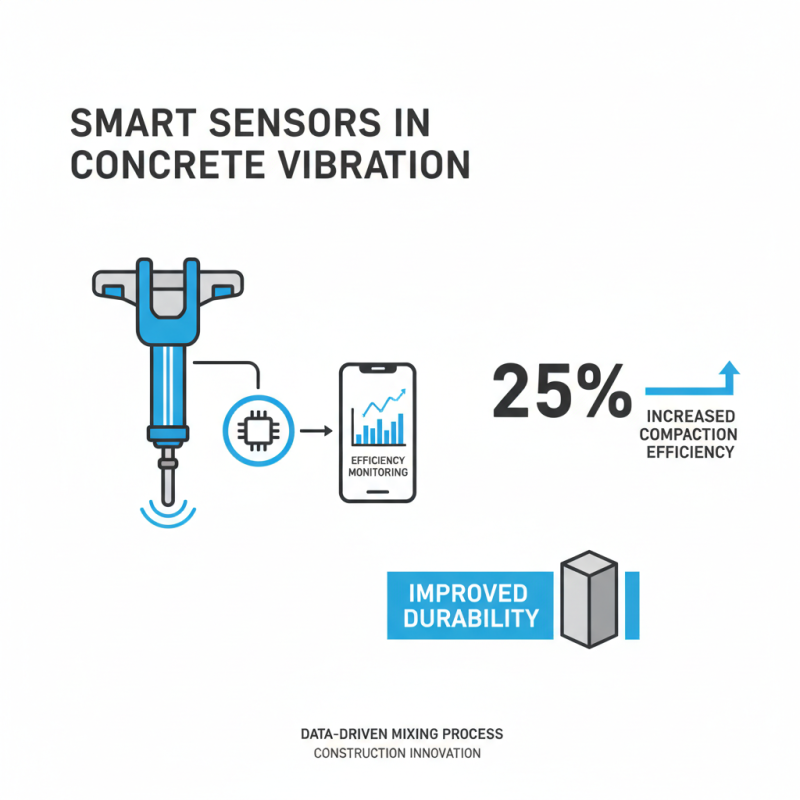

The Role of Smart Sensors in Monitoring Concrete Vibration Efficiency

The integration of smart sensors into concrete vibration tools is transforming the industry. These sensors monitor vibration efficiency in real time, providing valuable data on the mixing process. According to a recent market report, the use of advanced sensing technology can increase the efficiency of concrete compaction by up to 25%. This improvement can directly influence the durability of structures.

Smart sensors can detect inconsistencies in vibration patterns. They alert operators when the vibration is insufficient. Studies show that improper vibration can lead to up to 15% more voids in concrete, which affects overall strength. Real-time monitoring helps mitigate this risk, enhancing quality control on job sites.

However, reliance on technology also has downsides. Data overload is a real concern. Workers may struggle to interpret vast amounts of data effectively. There’s a need for better training and user-friendly interfaces. Additionally, sensor malfunctions can lead to missed alerts, potentially compromising projects. Industry experts emphasize continuous improvement in both technology and operator training to maximize benefits.

Sustainability Trends Impacting Concrete Vibrator Shaft Manufacturing

The concrete industry is evolving. Sustainability trends are shaping how manufacturers approach concrete vibrator shafts. Environmentally friendly materials are gaining traction. Companies are exploring the use of recycled components. This shift can lead to reduced waste and lower carbon footprints.

However, the challenges are significant. Sourcing sustainable materials may be difficult. Recycling processes are not always efficient. This raises questions about the quality and performance of the end products. Balancing sustainability with durability is a major concern for manufacturers.

Innovations in production techniques can support these goals. More companies are investing in energy-efficient machinery. This can reduce overall emissions during manufacturing. Additionally, improved design practices can minimize raw material usage. The industry must reflect on these factors to drive meaningful change. Embracing sustainability is essential, yet it requires careful consideration and action.

Market Analysis: Leading Brands and Innovations in Concrete Vibrator Shafts

The concrete vibrator shaft market is witnessing rapid innovations. New materials and designs are emerging, enhancing performance and durability. Manufacturers are focusing on lightweight options, allowing for easier handling on job sites. These advancements can improve efficiency during concrete pouring.

However, challenges remain. Not every new design meets the high standards required for different applications. Some tools may lack the necessary vibration power. There’s a constant balance between weight and effectiveness. Companies are experimenting with various shaft lengths to accommodate diverse project needs.

User feedback is essential in shaping future innovations. Many users are vocal about their experiences, highlighting areas for improvement. Clear communication between manufacturers and consumers drives better outcomes. Continuous iteration on designs is crucial, ensuring that new technologies address real-world issues rather than just trends.

2026 Top Concrete Vibrator Shaft Innovations and Trends to Watch

| Innovation/Trend |

Description |

Market Impact |

Sustainability Features |

Expected Growth Rate (%) |

| Wireless Technology |

Integration of wireless connectivity for real-time monitoring. |

Improves efficiency and reduces operational costs. |

Energy-efficient components. |

15% |

| Lightweight Materials |

Use of advanced composites to reduce weight. |

Enhances portability and reduces strain during use. |

Recyclable materials used in production. |

20% |

| Variable Frequency Drive (VFD) Integration |

Allows users to adjust vibration frequency. |

Optimizes performance for different concrete mixes. |

Maximizes energy efficiency. |

12% |

| Smart Sensors |

Monitoring concrete density and consistency in real-time. |

Reduces errors and improves mix quality. |

Saves materials by ensuring optimal use. |

18% |

| Noise Reduction Technology |

Design improvements to minimize operational noise. |

Enhances user comfort and complies with regulations. |

Using quieter, sustainable materials. |

10% |

Home

About Us

products

Resource

Blog

Contact Us

Internal Vibrator

Internal Vibrator

External Vibrator

External Vibrator

Submersible Pump

Submersible Pump

Eccentric shaft

Eccentric shaft

Pendulum shaft

Pendulum shaft

Portable vbrator shaft

Portable vbrator shaft

Portable concrete mixer

Portable concrete mixer

Vertical concrete mixer

Vertical concrete mixer

Hydraulic concrete mixer

Hydraulic concrete mixer

Walk behind power trowel

Walk behind power trowel

Ride on power trowel

Ride on power trowel

Concrete screed

Concrete screed

Tamping rammer

Tamping rammer

Plate compactor

Plate compactor

Vibratory roller

Vibratory roller